Plastic Recycling Machine: Turning Waste into Valuable Resources

A plastic recycling machine is a device designed to process used or discarded plastic materials into reusable raw materials. It plays a crucial role in reducing plastic waste, conserving resources, and promoting sustainability. This article explains what a plastic recycling machine is, its types, functions, benefits, and additional applications.

What is a Plastic Recycling Machine?

A plastic recycling machine is a system that cleans, shreds, melts, and reforms plastic waste into pellets or granules, which can be used to manufacture new products. It helps reduce environmental pollution and supports a circular economy.

Types of Plastic Recycling Machines

- Shredders:

- Break down large plastic items into smaller pieces for easier processing.

- Washing Lines:

- Clean plastic waste to remove contaminants like dirt and labels.

- Extruders:

- Melt and reform shredded plastic into pellets or granules.

- Pelletizers:

- Cut melted plastic into uniform pellets for reuse.

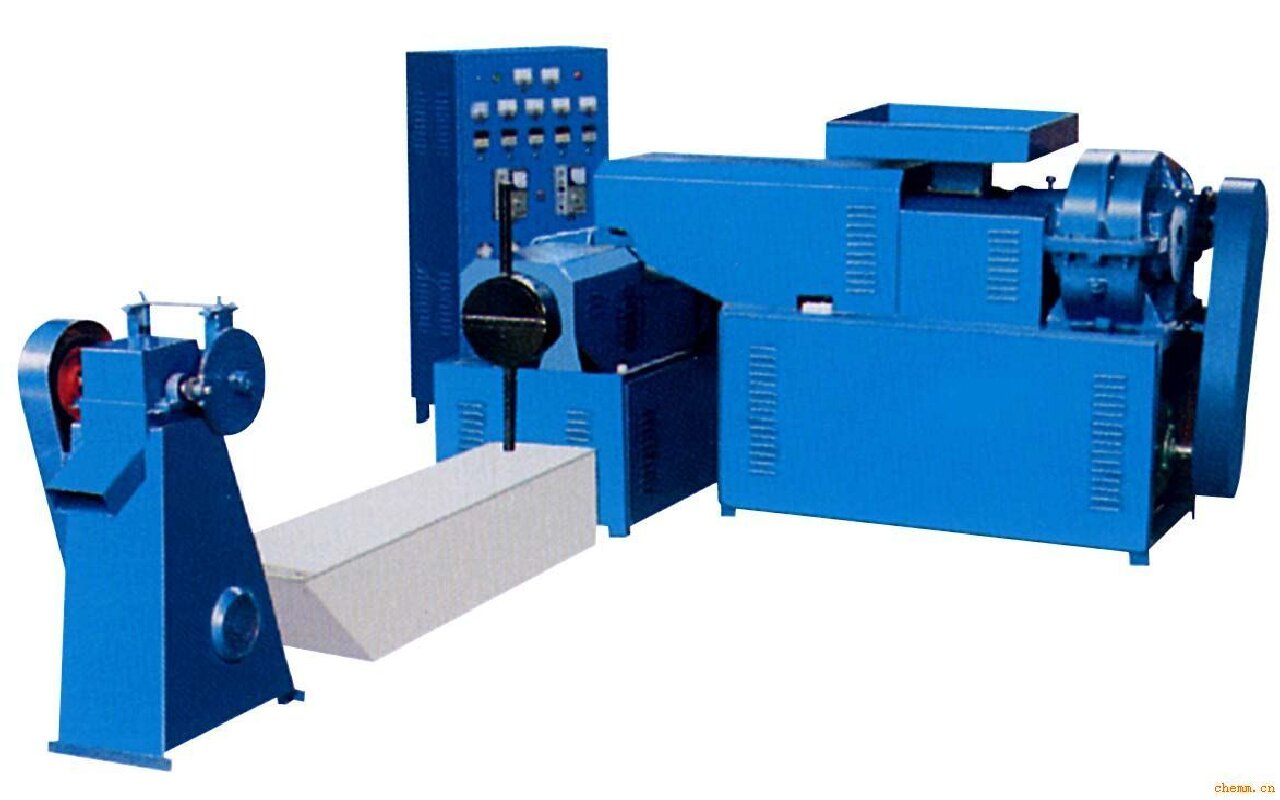

- Integrated Recycling Systems:

- Combine shredding, washing, and extrusion into one automated process.

Functions and Benefits

- Waste Reduction:

- Converts plastic waste into reusable materials, reducing landfill use.

- Resource Conservation:

- Saves raw materials by recycling existing plastics.

- Cost Savings:

- Lowers production costs by using recycled materials.

- Environmental Protection:

- Reduces plastic pollution and carbon emissions.

- Versatility:

- Can process various types of plastics, including PET, HDPE, and PVC.

Applications

- Recycling Facilities:

- Process large volumes of plastic waste for industrial use.

- Manufacturing Plants:

- Recycle plastic scraps into raw materials for new products.

- Small-Scale Recycling:

- Use compact machines for local or community recycling efforts.

- Waste Management:

- Convert plastic waste into reusable pellets for sale or reuse.

- Sustainability Initiatives:

- Support eco-friendly practices by recycling plastics.

Key Advantages Over Traditional Methods

- Efficiency:

- Automates the recycling process, saving time and labor.

- Scalability:

- Suitable for small-scale or large-scale operations.

- Economic Value:

- Turns waste into valuable resources, generating revenue.

Operation Steps

- Collection and Sorting:

- Gather and separate plastic waste by type.

- Shredding:

- Break down plastic into smaller pieces.

- Washing:

- Clean the shredded plastic to remove impurities.

- Extrusion and Pelletizing:

- Melt and reform the plastic into pellets or granules.

Maintenance Tips

- Clean shredders and extruders regularly to prevent clogging.

- Inspect and replace worn parts (e.g., blades, screws).

- Lubricate moving components to ensure smooth operation.

Conclusion

Plastic recycling machines are essential for reducing plastic waste and promoting sustainability. By converting discarded plastics into reusable materials, these machines support a circular economy and reduce environmental impact. Whether for large recycling facilities or small-scale initiatives, investing in plastic recycling technology ensures a cleaner and more sustainable future.