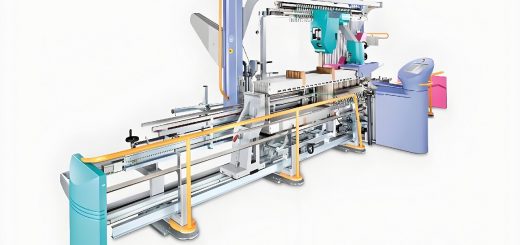

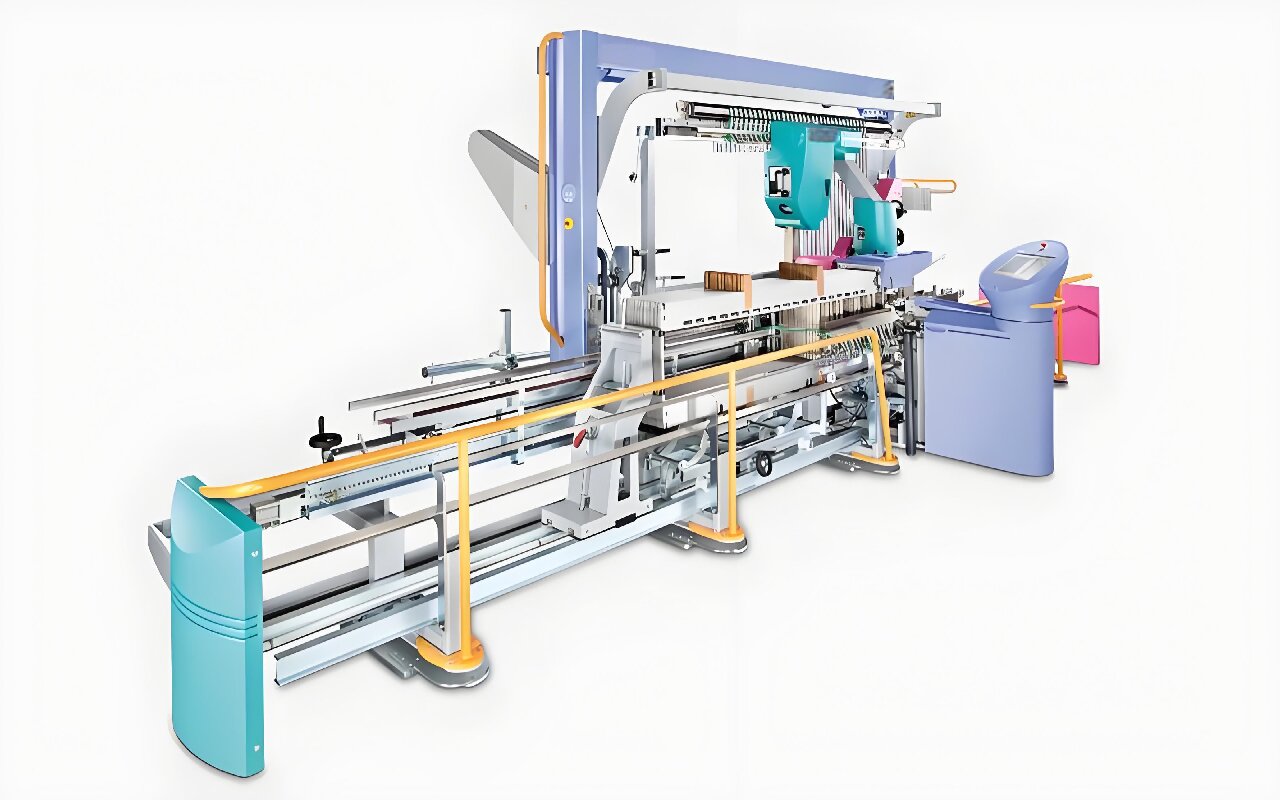

Plastic Drawing Machine: Enhancing Material Strength for Fibers, Films, and Industrial Components

Plastic drawing machines stretch heated polymer sheets or filaments to align molecular chains, significantly improving tensile strength and clarity in products like synthetic fibers and BOPP films.

What is a Plastic Drawing Machine?

It applies controlled tension to plastic substrates through heated rollers, inducing orientation for enhanced mechanical properties.

Types of Drawing Machines

- Uniaxial Stretchers:

- Stretch in one direction for monofilaments or strapping tapes.

- Biaxial Orientation Machines:

- Simultaneously stretch MD (machine direction) and TD (transverse direction) for films.

- Sequential Stretchers:

- Stretch sequentially for high-clarity packaging films.

- Fiber Draw Towers:

- Produce polyester or nylon fibers with precision diameter control.

Key Advantages

- Strength Enhancement: Increase tensile strength by 300–500%.

- Optical Clarity: Reduce haze in films for premium packaging.

- Thinness Control: Produce films as thin as 5 microns.

Applications

- Packaging: BOPP films for snack wrappers, shrink films.

- Textiles: High-tenacity PET fibers for ropes and seatbelts.

- Electronics: Optically clear films for touchscreens.

Operation Steps

- Preheating: Heat polymer to 80–150°C (below melting point).

- Drawing: Stretch material between rollers at controlled ratios (e.g., 1:4 for PET).

- Annealing: Heat-set to lock molecular orientation.

- Cooling & Winding: Solidify and roll finished product.

Technological Advances

- Laser Thickness Gauges: Real-time monitoring for ±1% thickness tolerance.

- Eco-Friendly Films: Draw biodegradable PLA for compostable packaging.