Oil Pressers: What They Are, Types, Functions, and Benefits in Oil Extraction

Oil pressers, also known as oil presses, are machines used to extract oil from seeds, nuts, and other oil-bearing materials. These devices play a crucial role in the production of edible oils, biofuels, and industrial oils. In this article, we will explore what oil pressers are, the different types available, their functions, and the advantages they offer in oil extraction processes.

What is an Oil Presser?

An oil presser is a mechanical device designed to extract oil from raw materials such as sunflower seeds, soybeans, peanuts, olives, and coconuts. It works by applying pressure to the material, forcing the oil to separate from the solid components. Oil pressers are widely used in both small-scale and large-scale oil production due to their efficiency and versatility.

Types of Oil Pressers

- Screw Oil Pressers: Screw oil pressers are the most common type, using a rotating screw to crush and press the oil-bearing material. The screw generates high pressure, which extracts the oil efficiently. These machines are suitable for a wide range of materials and are often used in small to medium-scale operations.

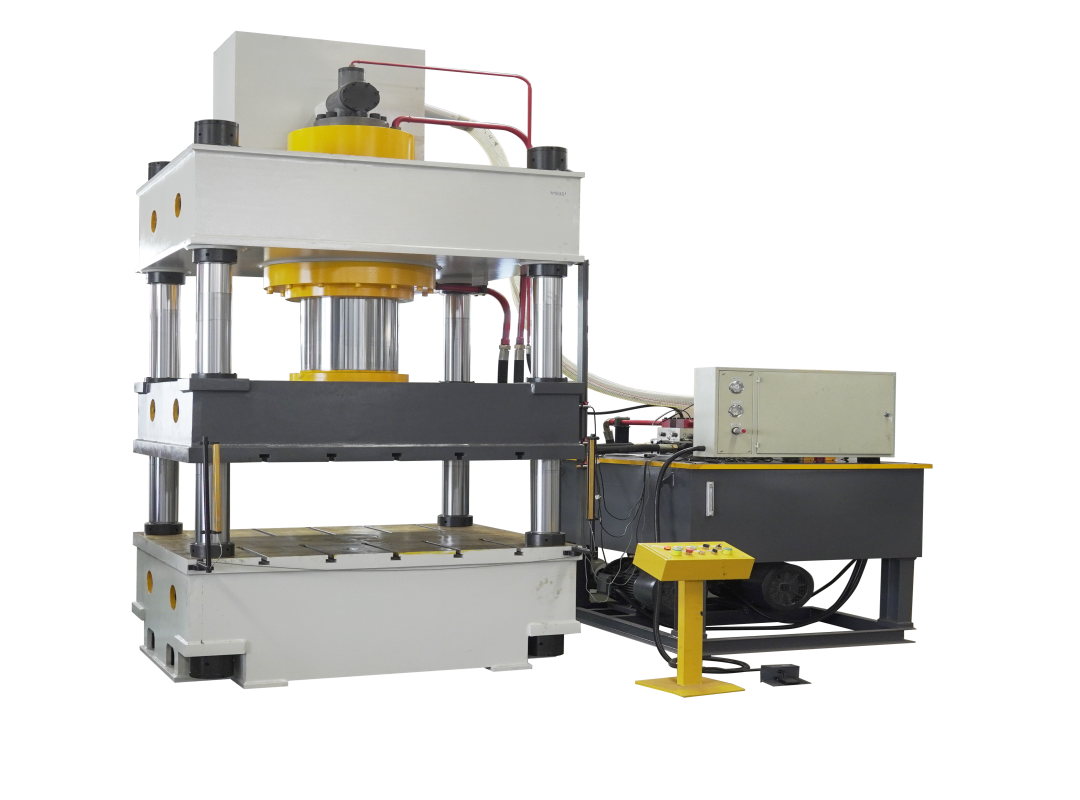

- Hydraulic Oil Pressers: Hydraulic oil pressers use hydraulic pressure to extract oil. They are typically slower than screw pressers but can handle larger volumes of material. These machines are ideal for large-scale industrial oil production and are known for their high oil yield.

- Cold Press Oil Pressers: Cold press oil pressers operate at low temperatures to preserve the natural flavor, color, and nutritional value of the oil. These machines are commonly used for producing high-quality edible oils, such as olive oil and coconut oil.

- Hot Press Oil Pressers: Hot press oil pressers use heat to extract oil, which increases the oil yield but may affect the oil’s quality. These machines are often used for materials that require higher temperatures to release oil, such as sesame seeds or rapeseed.

Functions of Oil Pressers

- Oil Extraction: The primary function of an oil presser is to extract oil from oil-bearing materials. This process is essential for producing edible oils, biofuels, and industrial oils.

- Separation of Oil and Solids: Oil pressers separate the oil from the solid residue, known as oil cake or meal. The oil cake can be used as animal feed or fertilizer, adding value to the by-products of oil extraction.

- Preservation of Oil Quality: Cold press oil pressers, in particular, help preserve the natural qualities of the oil, such as flavor, aroma, and nutritional content, making them ideal for high-quality edible oils.

- Versatility: Oil pressers can process a wide range of materials, from seeds and nuts to fruits and vegetables, making them versatile tools in the oil production industry.

Advantages of Oil Pressers

- High Efficiency: Oil pressers are highly efficient, capable of extracting a significant amount of oil from raw materials in a short time. This makes them ideal for both small-scale and large-scale operations.

- Cost-Effective: By automating the oil extraction process, oil pressers reduce labor costs and increase productivity, making them a cost-effective solution for oil producers.

- Environmentally Friendly: Oil pressers produce minimal waste, and the by-products (oil cake) can be reused, making them an environmentally friendly option for oil extraction.

- Preservation of Nutrients: Cold press oil pressers, in particular, help retain the natural nutrients and flavors of the oil, ensuring high-quality end products.

- Ease of Use: Modern oil pressers are designed to be user-friendly, with simple controls and maintenance requirements, making them accessible even for small-scale producers.

Conclusion

Oil pressers are indispensable tools in the oil extraction industry, offering numerous benefits such as high efficiency, cost-effectiveness, and the ability to preserve oil quality. Whether used for producing edible oils, biofuels, or industrial oils, these machines play a vital role in meeting the growing demand for oil products. As technology advances, oil pressers continue to evolve, becoming even more efficient and environmentally friendly.