Foam Machinery: Revolutionizing Lightweight Solutions Across Industries

Foam machinery is at the forefront of material innovation, enabling products that are lighter, greener, and smarter. From cushioning fragile goods to insulating skyscrapers, these machines transform raw polymers into versatile foams with precision. Let’s explore their technical complexity and market impact.

Advanced Foaming Techniques Explained

- Polyurethane (PU) Foaming:

- Two-Component Mixing: High-pressure machines blend polyols and isocyanates at 1:1 ratios, expanding into foam within seconds. Innovations like low-VOC formulations reduce workplace hazards.

- Applications: Car seats with variable firmness zones, eco-friendly mattresses using soy-based polyols.

- Expandable Polystyrene (EPS) Production:

- Steam Chest Molding: Pre-expanded EPS beads are fused using steam, creating insulation boards with R-values up to 4 per inch. Recent advancements allow 30% faster cycle times.

- Graphite-Infused EPS: Reflective additives improve thermal resistance by 20%, ideal for cold chain packaging.

- Cross-Linked Polyethylene (PE) Foam:

- Chemical vs. Radiation Cross-Linking: Machines using peroxides create closed-cell foams for yoga mats, while electron beam systems produce ultra-light foams for aerospace.

Sustainability in Foam Production

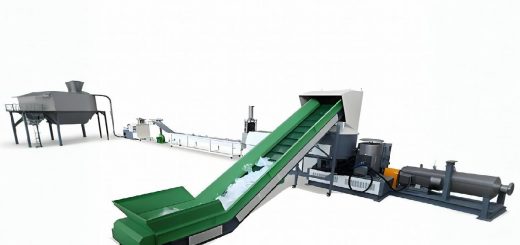

- Closed-Loop Recycling:

- Scrap foam is shredded and re-bonded into acoustic panels or playground surfaces. Companies like Dow have achieved zero landfill status in foam plants.

- Bio-Degradable Alternatives:

- Mycelium-based foams grown using agricultural waste are now compatible with modified molding machines.

Case Study: Foam in Electric Vehicles (EVs)

- Challenge: Reduce weight while dampening motor noise.

- Solution: Multi-density PU foam injected into door panels and battery housings.

- Outcome: 12% weight reduction per vehicle, meeting EU noise regulations.

Emerging Technologies

- AI-Optimized Density Control:

- Sensors adjust foaming agents in real-time to achieve precise cell structures.

- 3D Foam Printing:

- Additive manufacturing creates custom orthopedic shoe insoles with gradient firmness.