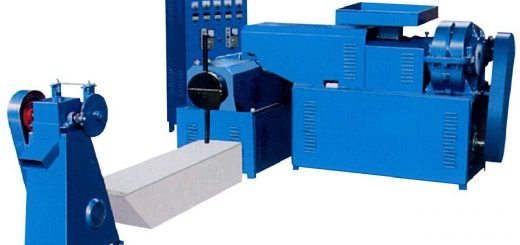

Feed Mixing Machines: Essential Tools for Consistent and Nutritious Animal Feed

Feed mixing machines are devices designed to blend various raw ingredients (e.g., grains, protein meals, vitamins) into a uniform mixture for animal feed. These machines ensure consistent nutrition, improve feed quality, and support efficient livestock, poultry, and aquaculture farming. This article explains what feed mixing machines are, their types, functions, benefits, and additional applications.

What is a Feed Mixing Machine?

A feed mixing machine is a mechanical device that combines different feed ingredients into a homogeneous mixture. It ensures that each portion of feed contains the same balance of nutrients, which is crucial for animal health and productivity.

Types of Feed Mixing Machines

- Horizontal Mixers:

- Use rotating blades or paddles to mix ingredients in a horizontal drum, ideal for large-scale feed production.

- Vertical Mixers:

- Feature a vertical screw that lifts and blends ingredients, suitable for small to medium farms.

- Batch Mixers:

- Mix a specific amount of feed at a time, ensuring precise control over ingredient ratios.

- Continuous Mixers:

- Blend ingredients continuously, ideal for high-volume feed factories.

- Portable Mixers:

- Compact and mobile units for small farms or on-site feed preparation.

Functions and Benefits

- Uniform Nutrition:

- Ensures every bite of feed contains the same nutrients, promoting balanced diets.

- Improved Feed Quality:

- Thorough mixing prevents ingredient separation and enhances digestibility.

- Cost Savings:

- Efficient mixing reduces ingredient waste and lowers feed production costs.

- Time Efficiency:

- Automates the mixing process, saving labor and time compared to manual methods.

- Versatility:

- Can handle a wide range of ingredients, from grains to powdered supplements.

Applications

- Livestock Farming:

- Mix feed for cattle, pigs, or sheep to support growth and milk production.

- Poultry Farming:

- Blend balanced diets for chickens, ducks, or turkeys.

- Aquaculture:

- Prepare feed mixtures for fish or shrimp farming.

- Feed Mills:

- Produce large quantities of feed for commercial distribution.

- Small-Scale Farms:

- Affordable mixers for local farmers to create custom feed blends.

Key Advantages Over Traditional Mixing Methods

- Consistency:

- Machines ensure even distribution of ingredients, unlike manual mixing.

- Scalability:

- Suitable for small farms or large feed factories.

- Reduced Labor:

- Automates a labor-intensive task, freeing up workers for other activities.

Operation Steps

- Loading Ingredients:

- Add raw materials (e.g., grains, protein meals, vitamins) into the mixer.

- Mixing:

- Activate the machine to blend ingredients for a set time.

- Discharge:

- Release the mixed feed into storage bins or directly into feeding systems.

- Cleaning:

- Clean the mixer after use to prevent cross-contamination.

Maintenance Tips

- Regularly inspect and tighten bolts, blades, or screws to ensure smooth operation.

- Lubricate moving parts to reduce wear and tear.

- Clean the mixer thoroughly after each use to prevent residue buildup.

Conclusion

Feed mixing machines are indispensable for modern animal farming, offering efficiency, consistency, and cost savings. By producing high-quality, uniform feed blends, these machines support healthy animal growth and sustainable farming practices. Whether for large feed mills or small family farms, investing in a feed mixing machine ensures optimal nutrition and productivity for livestock, poultry, and aquaculture.