Bottle Blowing Machine: Revolutionizing High-Speed Production of Lightweight Containers

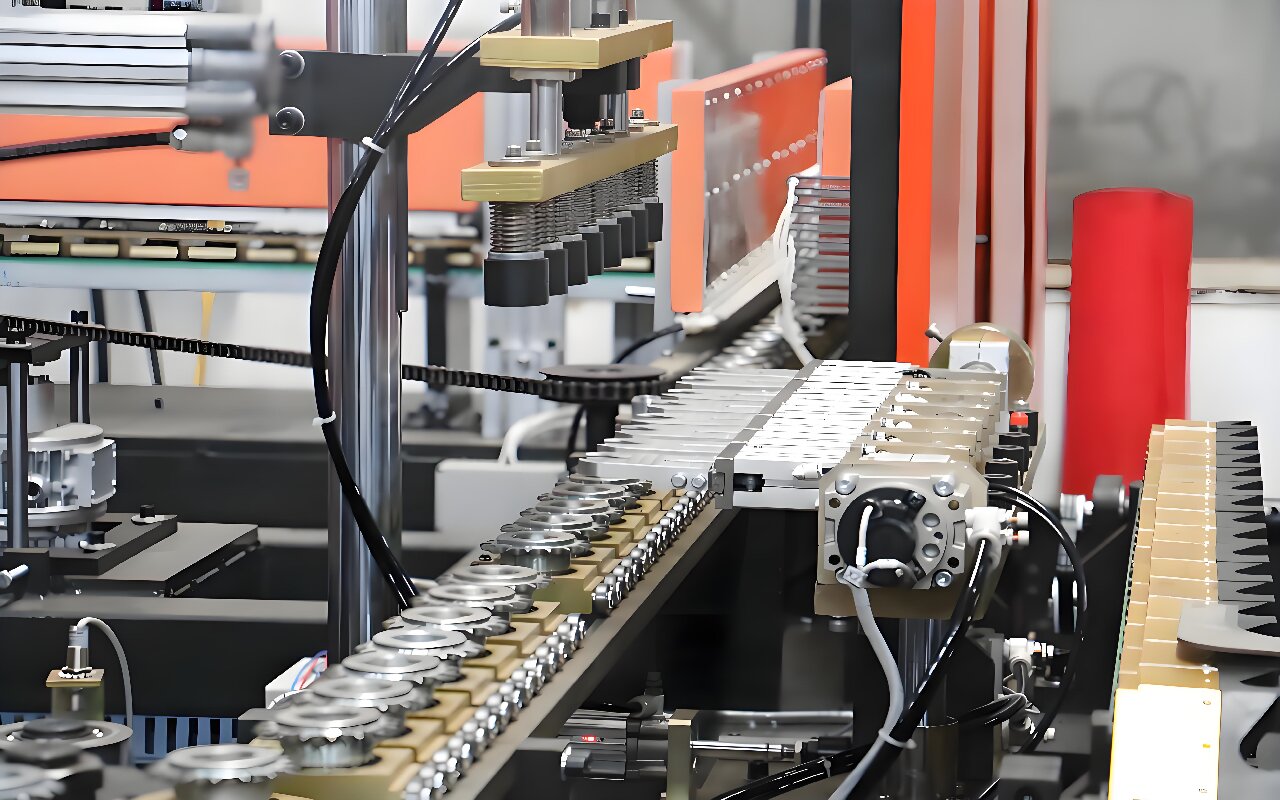

Bottle blowing machines transform preforms into PET, HDPE, or PP bottles using stretch blow molding technology. These machines dominate the beverage, pharmaceutical, and cosmetics industries by delivering millions of uniform containers daily.

What is a Bottle Blowing Machine?

It heats preforms (injection-molded tube-like forms) and inflates them into bottles using compressed air. Advanced models integrate automation for filling and capping.

Types of Blowing Machines

- Single-Stage Machines:

- Combines injection molding and blowing in one cycle. Ideal for small batches (e.g., cosmetic bottles).

- Two-Stage Machines:

- Preforms are molded separately, then reheated and blown. Suited for high-speed beverage production (2,000 bottles/hour).

- Rotary Blow Molders:

- Multi-cavity systems for bulk production (e.g., 20-cavity setups for water bottles).

- ECO-Blow Machines:

- Energy-efficient models using 30% less compressed air.

Core Benefits

- Lightweighting: Produce bottles with 10–15% less material without compromising strength.

- Speed: Output up to 50,000 bottles per hour in large facilities.

- Versatility: Switch between bottle designs (round, square, handles) via quick mold changes.

Key Applications

- Beverages: PET bottles for water, soda, and juices.

- Pharma: Sterile HDPE bottles for syrups and tablets.

- Household Chemicals: Detergent bottles with ergonomic grips.

Operational Workflow

- Preform Loading: Feed preforms into the heating oven (100–120°C for PET).

- Stretch Blowing: Stretch rods elongate preforms vertically; air inflates them horizontally.

- Cooling and Ejection: Cool molds with water channels; robots remove finished bottles.

- Quality Control: Check wall thickness with laser sensors.

Innovations in Blowing Technology

- Hybrid Heating: Infrared and convection heating for uniform preform expansion.

- AI-Driven Optimization: Adjust air pressure in real-time based on preform temperature.

- Recycled PET Compatibility: Machines adapted to handle 100% rPET preforms.