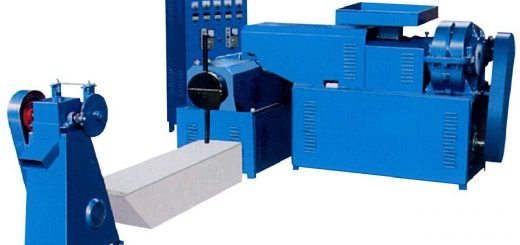

Blow Molding Machine: Crafting Hollow Plastic Products with Efficiency

A blow molding machine is a device used to create hollow plastic products like bottles, containers, and tanks by inflating molten plastic into a mold. It is essential in packaging, automotive, and industrial manufacturing. This article explains what a blow molding machine is, its types, functions, benefits, and applications.

What is a Blow Molding Machine?

A blow molding machine heats plastic into a parison (hollow tube), places it in a mold, and inflates it with air to form the desired shape. The process is ideal for lightweight, durable containers.

Types of Blow Molding Machines

- Extrusion Blow Molding:

- Extrudes a parison and inflates it into a mold; used for bottles and drums.

- Injection Blow Molding:

- Combines injection molding and blow molding for high-precision medical or cosmetic bottles.

- Stretch Blow Molding:

- Stretches and inflates preforms (e.g., PET bottles) for enhanced strength.

- Rotational Blow Molding:

- Rotates molds to create large, complex shapes like fuel tanks.

Functions and Benefits

- Lightweight Design:

- Produces durable, thin-walled containers.

- Cost-Effective:

- Low material waste and high production speed.

- Versatility:

- Creates bottles, tanks, and automotive parts.

- High Volume Production:

- Suitable for mass manufacturing.

- Material Flexibility:

- Works with HDPE, PET, PVC, and other plastics.

Applications

- Packaging:

- Produce bottles for beverages, chemicals, and cosmetics.

- Automotive:

- Manufacture fuel tanks, air ducts, and fluid containers.

- Industrial:

- Create storage drums and chemical tanks.

- Consumer Goods:

- Make household containers and toys.

Key Advantages Over Traditional Methods

- Speed:

- Faster than manual or glass-based production.

- Uniformity:

- Ensures consistent product quality.

- Scalability:

- Adaptable to small or large production runs.

Operation Steps

- Parison Formation:

- Extrude or inject a hollow plastic tube.

- Mold Clamping:

- Secure the mold around the parison.

- Inflation:

- Blow air to expand the parison into the mold shape.

- Cooling and Ejection:

- Cool the product and remove it from the mold.

Maintenance Tips

- Clean molds and air nozzles regularly.

- Inspect heating elements for efficiency.

- Lubricate mechanical parts to prevent wear.

Conclusion

Blow molding machines are vital for producing hollow plastic products efficiently and cost-effectively. From packaging to automotive parts, these machines enable high-quality, large-scale production.