Chemical Hardening Sand Casting Parts Mould Low Pressure CNC Machining - AIA-1

Chemical Hardening Sand Casting Parts Mould Low Pressure CNC Machining For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale Chemical Hardening Sand Casting Parts Mould Low Pressure CNC Machining, Made in China, High Quality Products!, China cheap prodocuts, china suppliers Supplier, Manufacturer.

Chemical Hardening Sand Casting Parts Mould Low Pressure CNC Machining

?

Product?Descriptions:

?

Metal casting including: sand casting, precision casting, investment casting, die casting, forging and cnc machining, Usually material: iron, steel, aluminium, bronze, alloy.

?

We produce and supply:

1 . Die Castings: Aluminum(Al) Die Castings, Zinc(Zn) Die Castings

2 . Metal Pattern Gravity Casting(PermanentMould/PermanentMold/PermanentMolding

Castings/Permanent Moulding Castings):

Aluminum Metal Pattern Gravity Castings, Aluminum (Permanent Mould/Permanent Mold/Permanent Molding/Permanent Moulding)Gravity Castings

3 . Sand Castings: Aluminum Sand Castings, Iron Sand Castings, Steel Sand Castings

4 . Low Pressure Die Castings: Aluminum Low Pressure Die Castings.

5 . Investment Castings(Precision Castings/Lost Wax Castings): Alloy Steel Investment Castings(Precision Castings), Carbon Steel Investment Castings(Precision Castings), Carbon Steel Lost Wax Castings, Stainless Steel Investment Castings(Precision Castings) Stainless Steel Lost Wax Castings.

6 . Cast Iron: Grey Iron castings/Gray Iron Castings, Malleable Iron Castings, Ductile Iron Castings, with Coated Sand Casting & Green Resin Sand Castings & Sand Castings

7 . Steel Castings & Non Ferrous Metals (Al, Zn etc., ) with process of Sand Castings (Coated Sands & Green Resin sands), Complex Castings, Investment Castings (Water Glass/Sodium Silicate/ Silicon Lost Wax Investment Castings), Die Casting & Metal Pattern Gravity Casting etc.,

About us:

?

Our main product line includes sand casting, precision casting, forging and CNC turning. Materials vary from grey iron, ductile iron, bronze, aluminum, steel, stainless steel, and so on.

Shenzhen jintaihua Metal ?Co., Ltd. Jointly manufactures and exports a variety of casting products for architectural, automotive, mechanical parts. We export to more than 20 countries on 6 continents and have been doing so for more than 10 years.

We have a strong and highly efficient R&D team which can design and make OEM/ODM products according to your ideas and samples.

?

- - - -

PROCESS | MATERIAL | STANDARD |

S?AND

CASTING | Green Sand | Grey Iron, Ductile Iron, Malleable Iron, Stanless Steel, Carbon, Steel, Aluminium, Brass, Bronze | ASTM

BS

JIS

DIN

etc |

Furan Resin Sand |

Cold Harden Resin Sand |

INVESTMENT

CASTING | Sodium Silicone (Water galss) | Stainless Steel, Carbon Steel, Special Alloy Steel Bronze, Brass, Aluminum |

Silica Sol |

FORGING | Hammer Forging | Stainless Steel, Carbon Steel, Alloy Streel, Brass, Aluminum |

Die Forging |

Roll Forging |

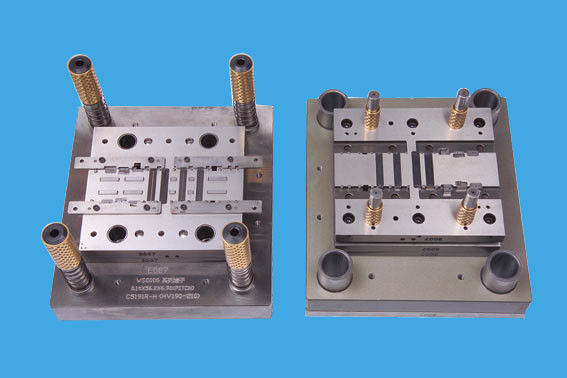

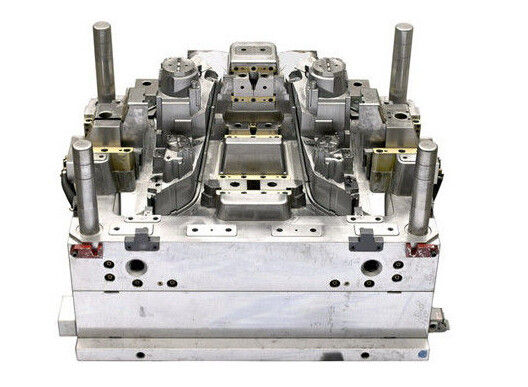

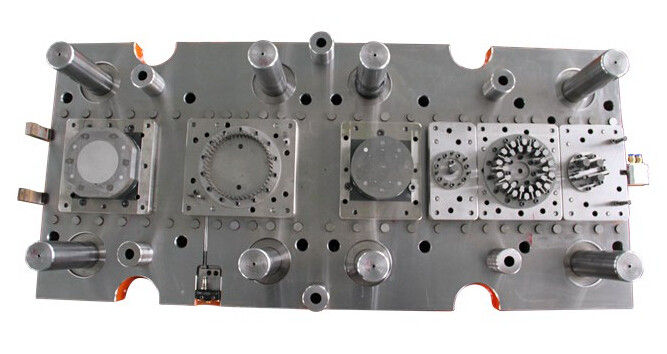

STAMPING MACHINING | STAMPING MACHINING | All metal material |

- - - -

Jintaihua Precision Molds Co.,Ld

Address: China guangdong shenzhen baoan district, Shenzhen, Guangdong, China, 518000

Tel: 86-135-90287963

Shenzhen Jin Taihua metal products co., LTD. Was established in June 2000, is located in baoan shajing xinqiao furong industrial zone, convenient transportation and superior geographical environment, is a professional engaged in precision metal mold design and production, metal stamping products, accessories, all kinds of oven door buckle, locks and chassis cabinets manufacturing, precision machinery parts processing, non-standard equipment design and manufacture of professional manufacturers. Now has complete production with the CNC computer gongs, computer lathe, automatic lathe, CNC milling machine, surface grinding machine, shearing machine, bending machine, line cutting machine, 16 t - 100 t punching machines and other processing equipment more than 80, the company factory building area of more than 1800 square meters, more than 100 employees, including research and development and technical personnel for 3 people, quality management personnel 8 people, production and technical personnel account for five people. Insist on development, innovation, quality, service, good faith for the company development.