Cement Vertical Mill - Cement Vertical Mill

Cement Vertical Mill For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale Cement Vertical Mill, Made in China, High Quality Products!, China Cement Vertical Mill, cement making machine Supplier, Manufacturer.

The main structure and function of Cement Vertical Mill:

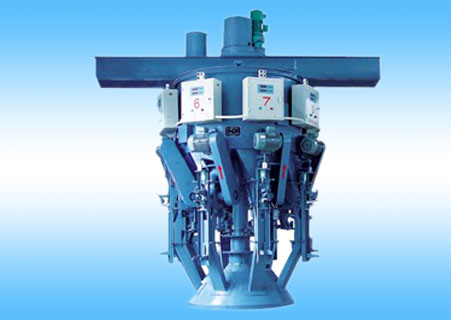

Grinding roller is the main components for materials rolling and grinding. Mill is equipped with two pairs of grinding roller, each pair of grinding rollers mounted on the same axis with different rotating speed. Disc of grinder is fixed in the output shaft of reducer and upper part of the disc is the material bed which has annular groove. PRM-type vertical mill is composed of the separator, roller disc, compression device, reducer, motor, shell and other parts. The separator is an important component to decide fineness and it is made up of adjustable speed gear, rotor and guide blades, shell, meals off the material cone hopper, the outlet. The working principle is similar to powder concentrator machine. Pressure device is to support the components so called grinding pressure and the composition mainly contains the high-pressure filling stations, hydraulic cylinder, lever and storage, etc., exert enough pressure to make the material grinding to the grinding rollers.

Working principles of Cement Vertical Mill:

Materials in the air flow go through the separator by the role of guide vanes and rotor, the crude material from the cone bucket on to the disc. Fine powder with a mill with the air ca be collected in the collecting device in the system that product materials are dried and gas contact process to reach the required water, adjust the angle of the wind guide blades and the separator rotor speed can achieve different fineness of products.

Motor is driven by reducer to reduce the rotation speed. The existing hot air from the air inlets into the mill and the material falls from the feed opening disc central; Due to the centrifugal force, materials move to the disc edge, through the annular groove on the disc by the grinding roller RCC and grinding, continue to move to the disc edge, until brought up the airflow at the wind. The large particles fall directly back to the re-grinding on the disc.

Gongyi Fuwei Heavy Machinery Plant

Address: Mid Xinxing Road, Gongyi City, zhengzhou, henan, China, 450000

Tel: 0086-371-60263088

銆?銆?Henan Fuwei Heavy Industrial Machinery Co.,Ltd.,with the history of more than 20 years since its foundation, is a large bone enterprise mainly engaged in production of complete set metallurgy building materials and mine equipments and integrating scientific research, production and sales into one.

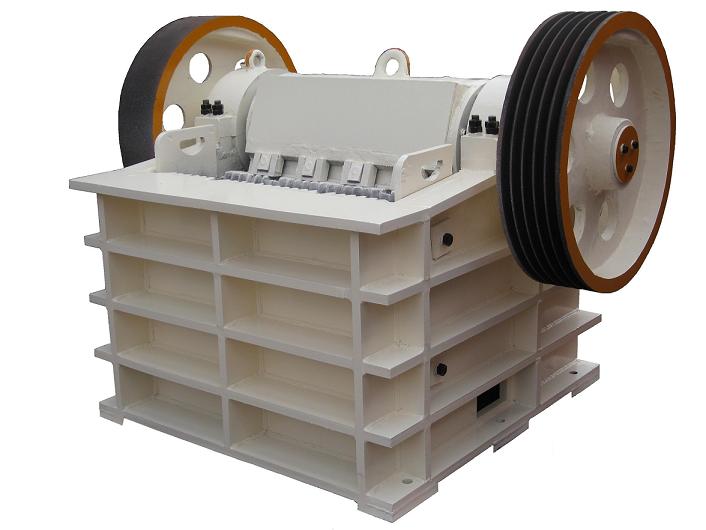

銆?銆?Main products of our company includes:aerated concrete equipments,baking-free brick presses,mine processing equipments,sandstone production lines, sand-making equipments, high efficiency and energy saving conical ball mills, rod mills, wet pan mills, magnetic separators, jaw crushers, baffle crushers,hammer crushers, rolling mills, production lines of cold rolling reinforcing steel with ribs and other fitting equipments. They are widely used in metallurgy, mining, chemical, building materials, coal, refractory materials, electric power, ceramics and other industries. Meanwhile, our company is able to provide for customers with project design, technical process design, design and production of standard and non-standard products. Create market with service, lead market with brand! We sincerely welcome old and new clients to come to guide and negotiate business!