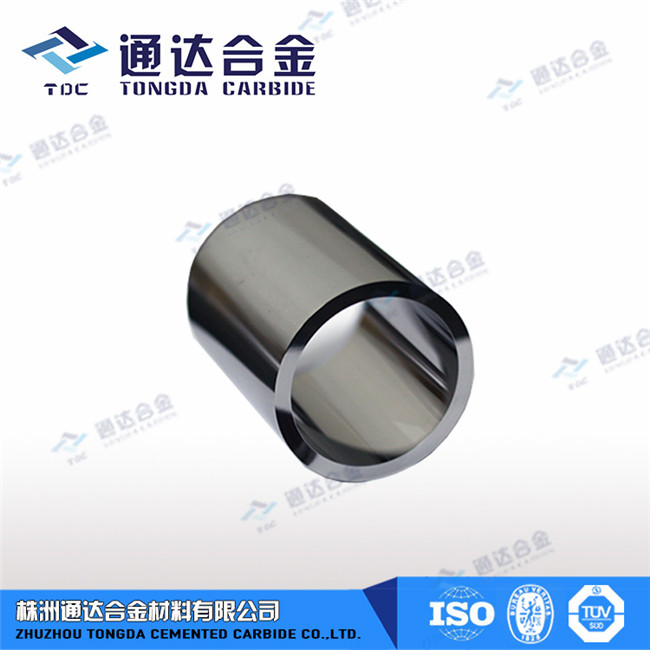

Carbide Grinding Tank - TDC-4

Carbide Grinding Tank For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale Carbide Grinding Tank, Made in China, High Quality Products!, China Carbide Grinding Tank, Grinding Tank Supplier, Manufacturer.

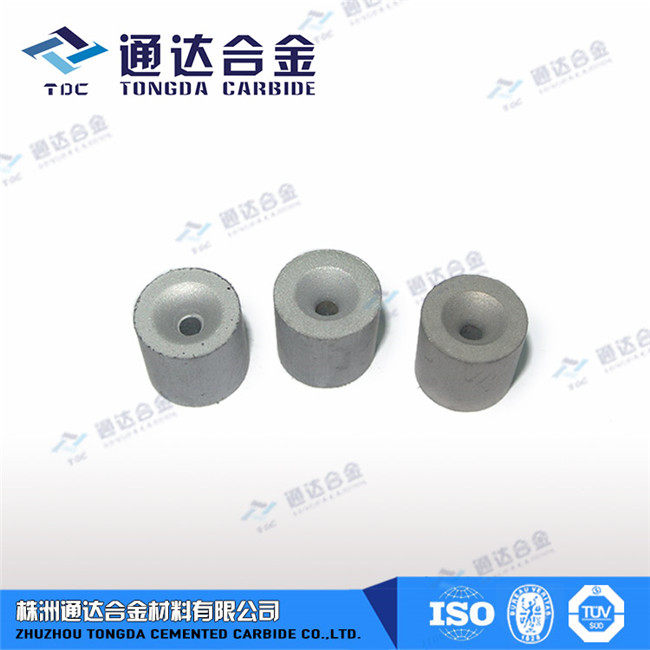

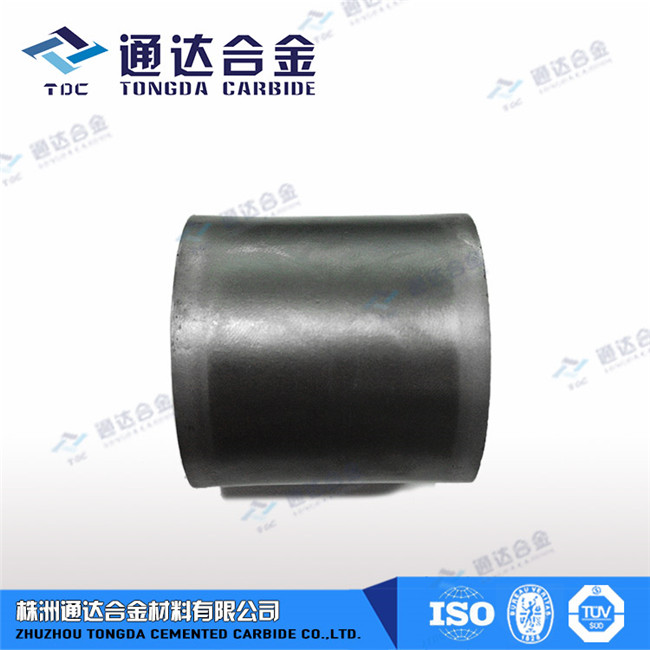

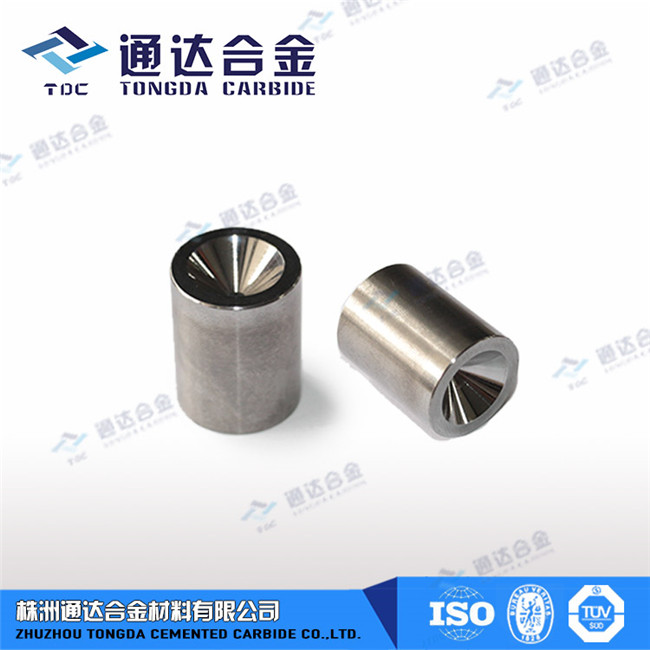

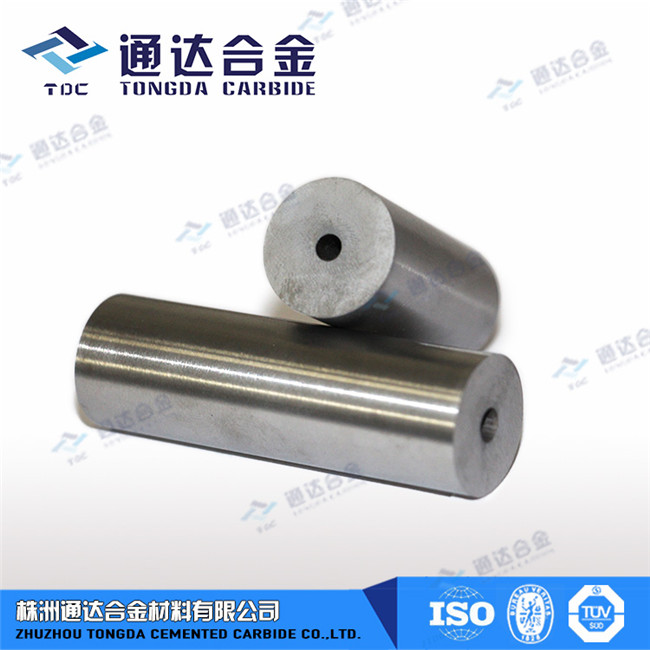

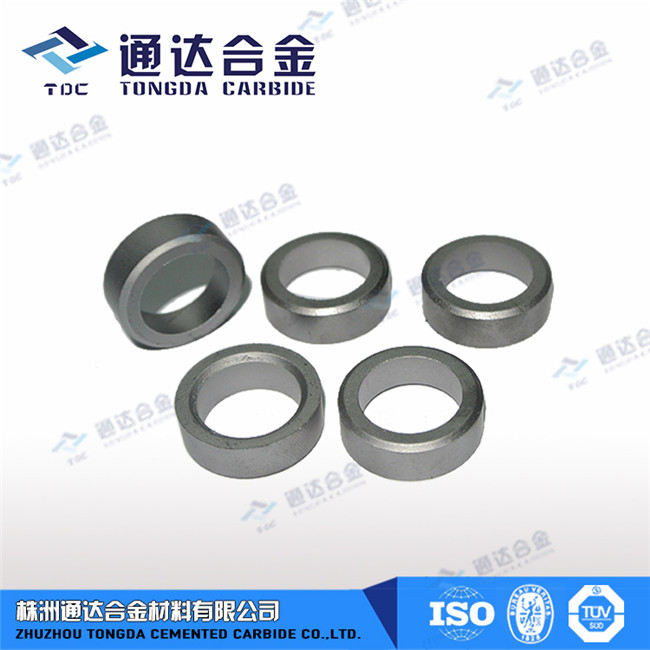

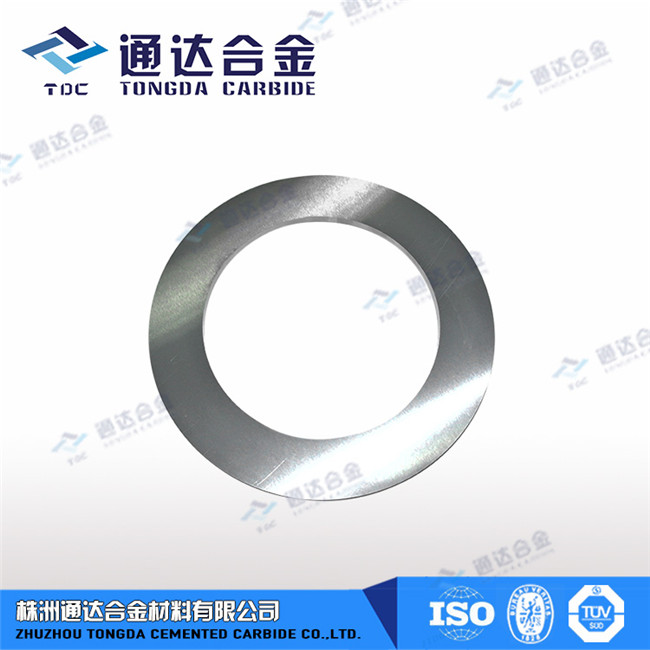

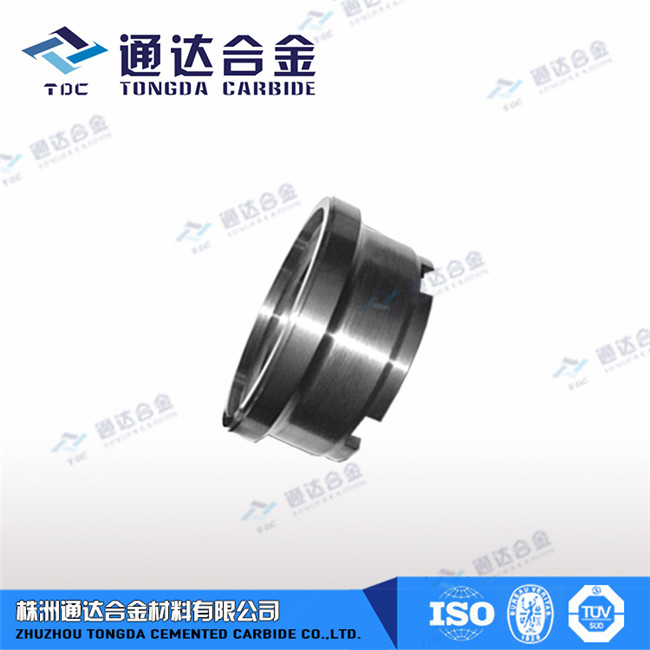

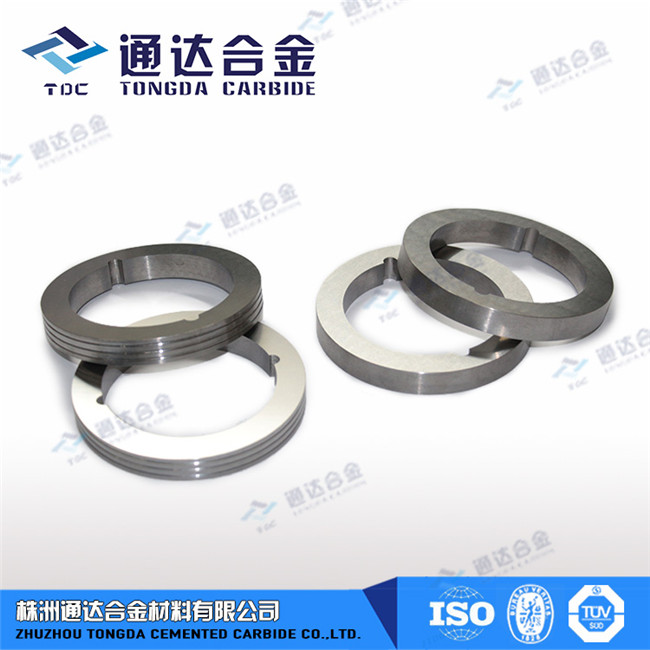

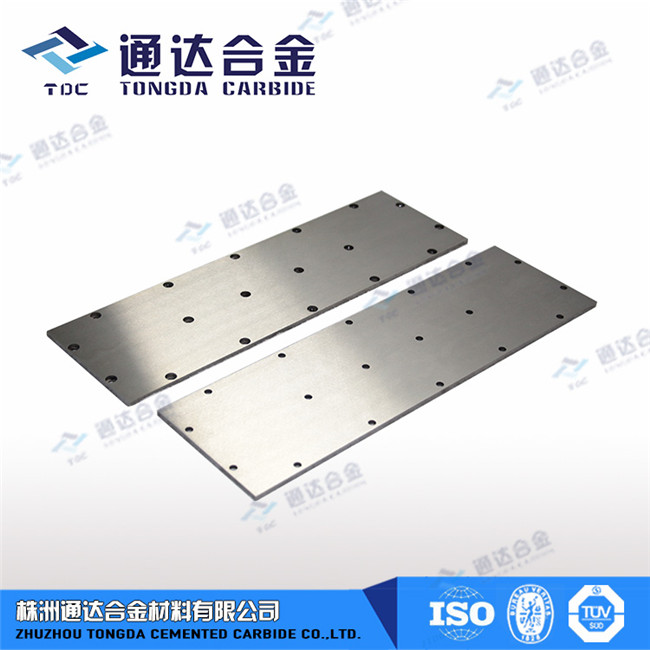

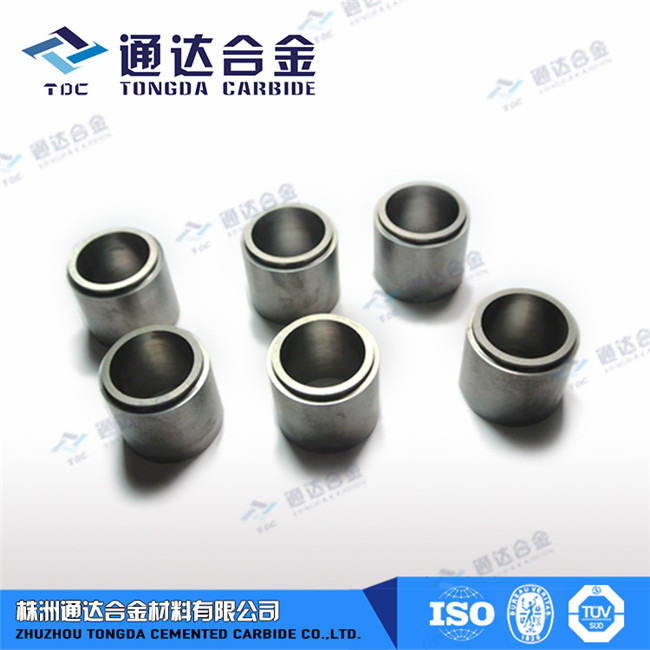

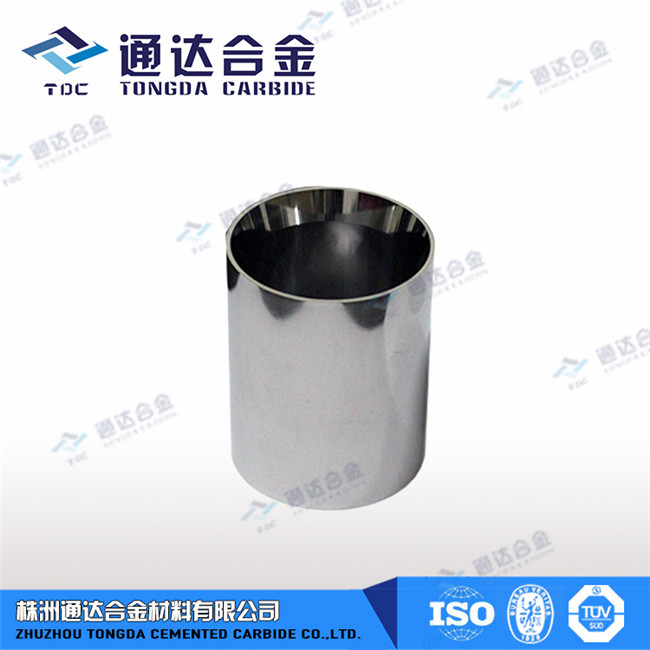

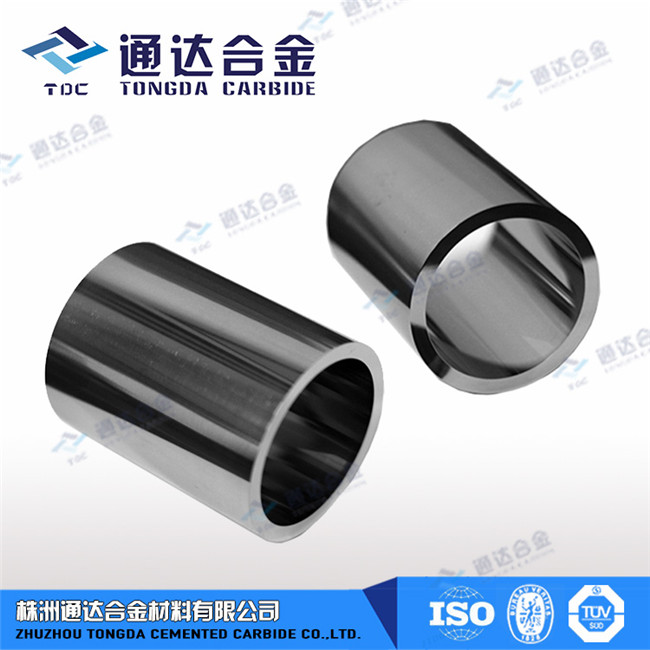

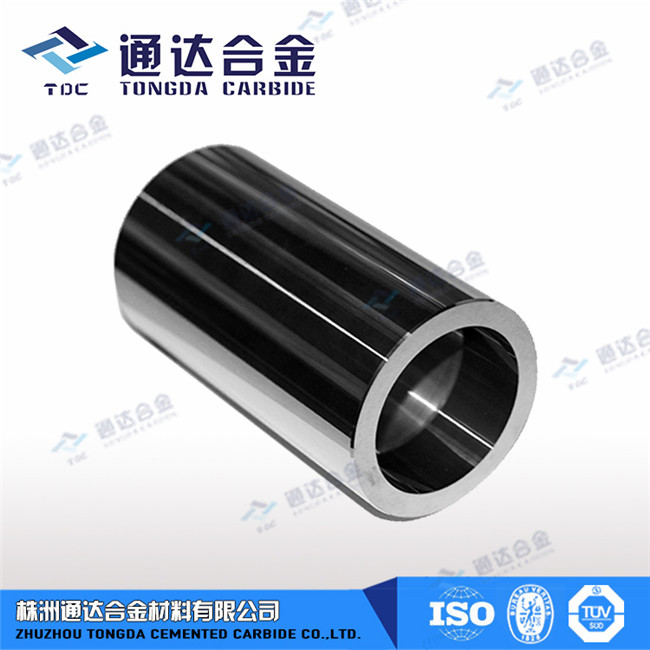

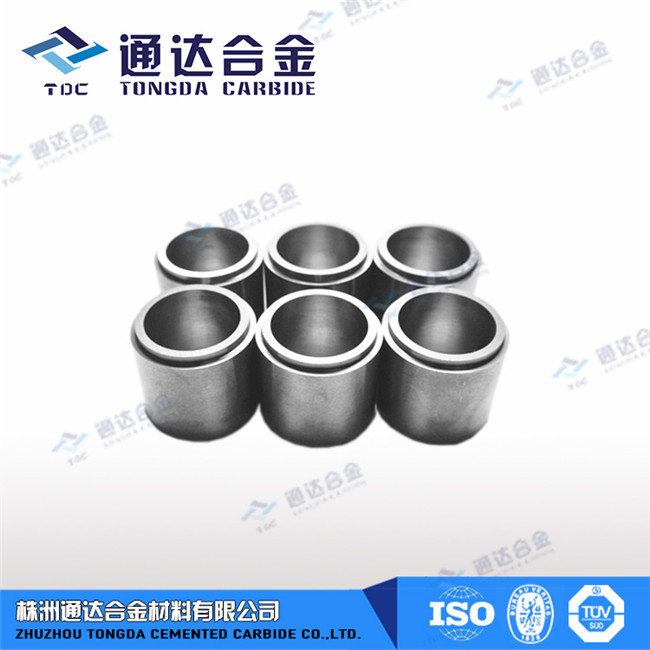

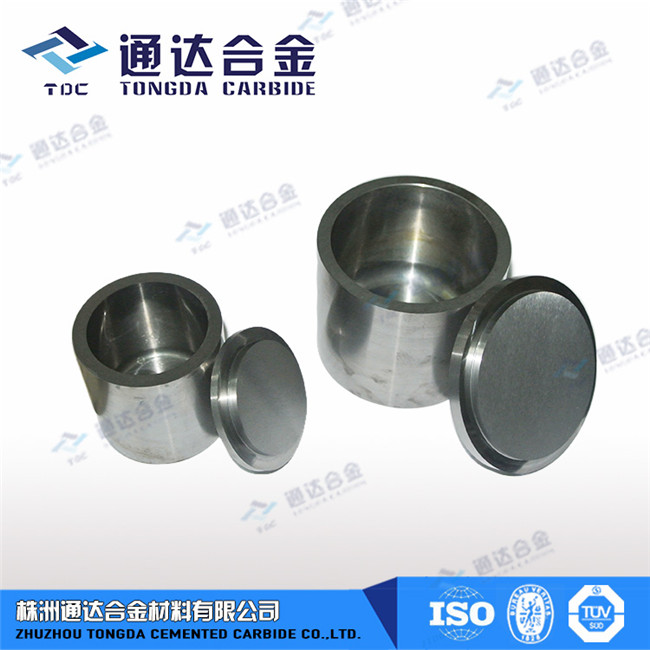

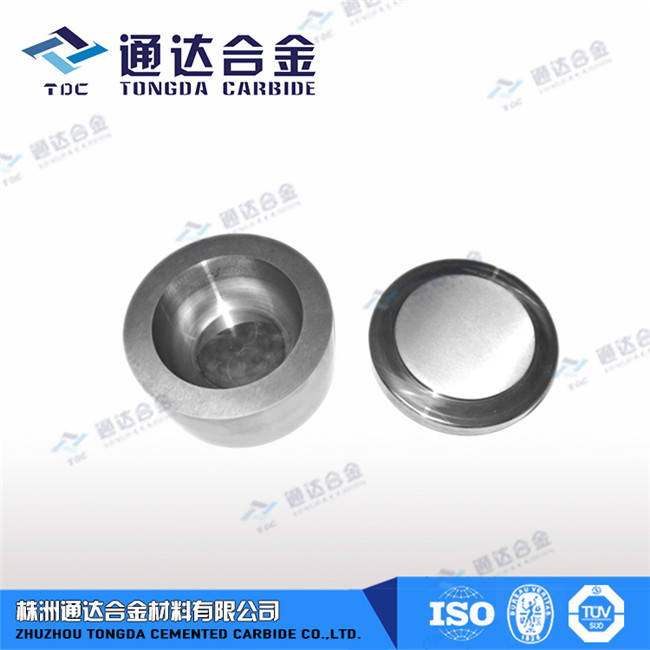

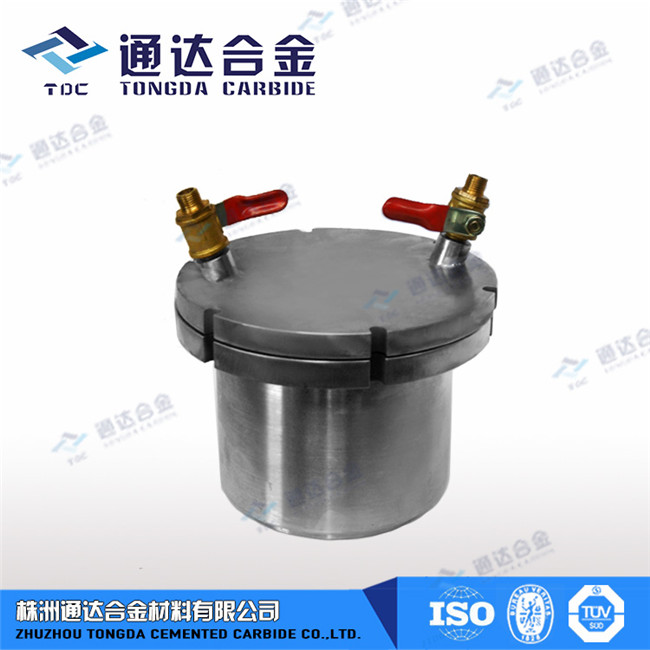

Tungsten carbide grinding tank, highly wear-resistant and resistant to acid and alkali. High hardness, can meet the vast majority of metal powder crushing and refining. Each jar set includes grinding tank, lid, rubber sealing gasket and mixed tungsten carbide grinding balls. The grinding tank are extensively applied to in the fields of Metallurgy, Ceramics, Electronics, Light Industry, Paint, Medicine, Geology, Chemical Engineering and so on.

Features

Acid and alkali resistant; heat resistant; very good wear resistant; anti-oxidation

Grinding tank can be made in customized sizes to meet all kinds of requirements of planetary ball mills

High hardness, can meet the vast majority of metal powder crushing and refining.

Descriptions

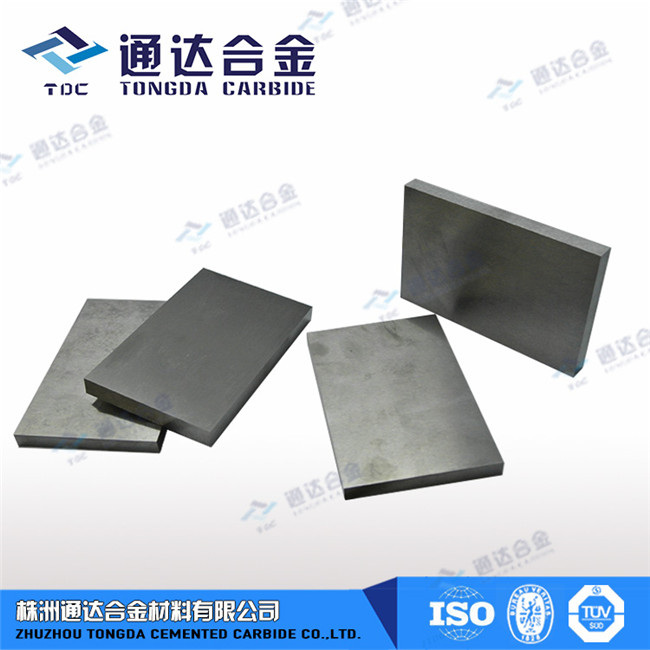

Item No. : WC-(50 ml -30000 ml)

Main Material : Tungsten Carbide --WC-YG8

Jar Volume : 50 mL~30000 mL

Max Loading Capacity : 2/3 capacity of the grinding jar

Density : 14.95g/cm3

Main Chemical Compositions : WC (92%), Cobalt (8%)

Surface Treatment : blank finish

Abrasion Resistance : very good

Grinding Balls : mixed Tungsten Carbide ball (should be ordered separately)

Hardness : 92.1 HRA

Suitable for : hard and abrasive samples

Choice of Grinding Jars & Balls

In order to prevent excessive abrasion, the hardness of the grinding tank used and of the grinding balls must be higher than that of the material grinded. Normally grinding tank and grinding balls of the same material should be choosen.

The size of the grinding tank and grinding balls should be determined experimentally if necessary.

Zhuzhou Tongda Cemented Carbide Co., Ltd

Address: Xintangpo, Hongqi Road, Zhuzhou, Hunan, China, 412000

Tel: +8673128167654

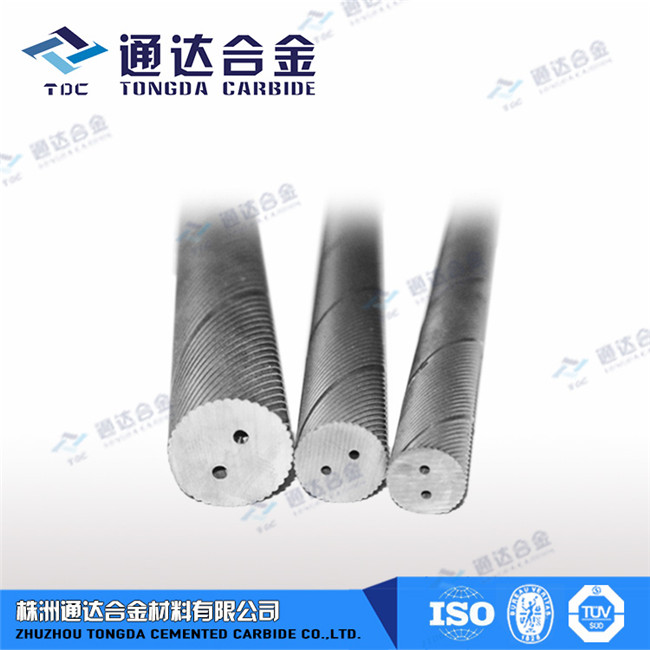

銆?銆?Zhuzhou Tongda Cemented Carbide Co., Ltd is a professional company which is contributed to study and manufacturer and serve carbide wear-resistance material. For many years, our company rely on progressive production equipment and strong technician strength, constantly studying advanced technology from Switzerland, Germany and America, etc. Combining the valuable feedback from customers, taking advantage of local tungsten carbide and ceramic material, has developed various grinding and dispersion parts which had been reached domestic first-class grade.

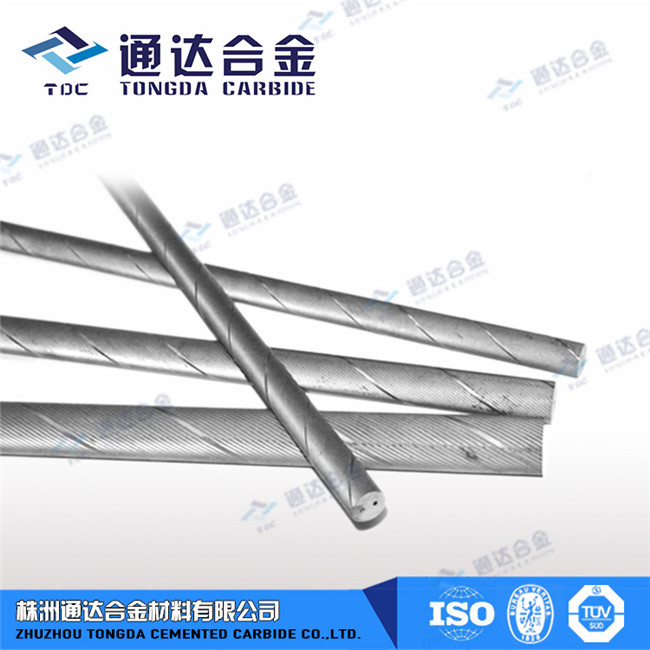

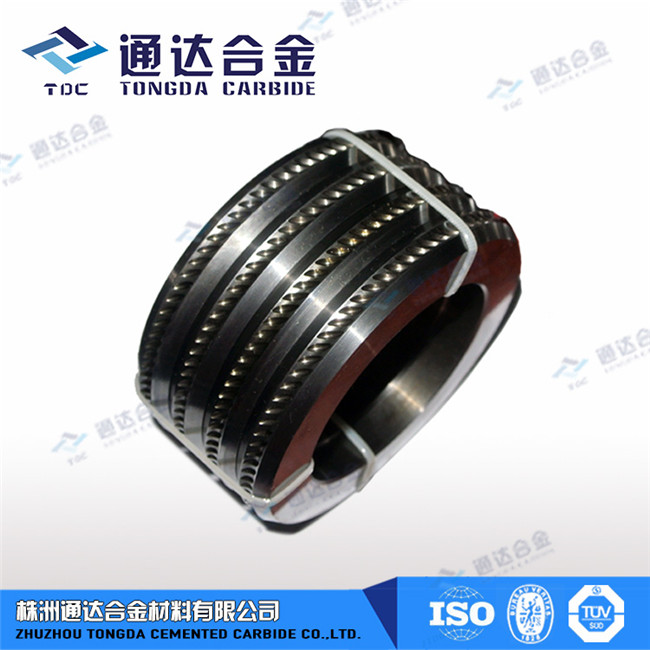

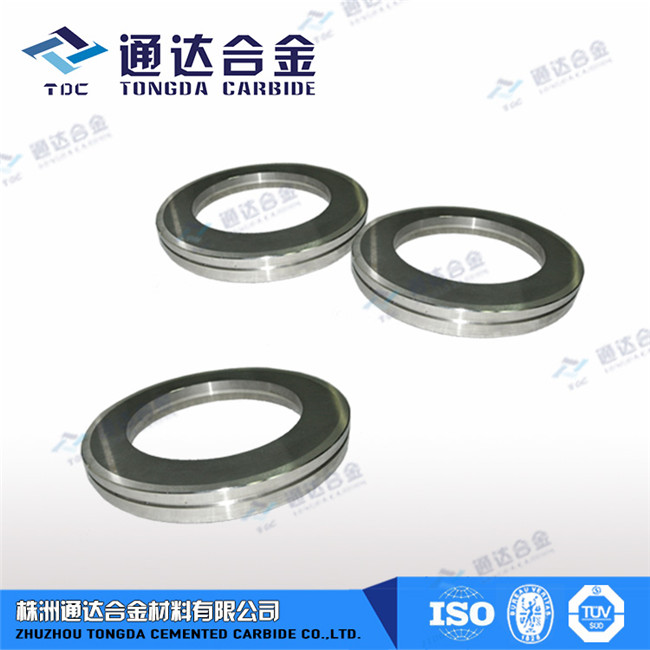

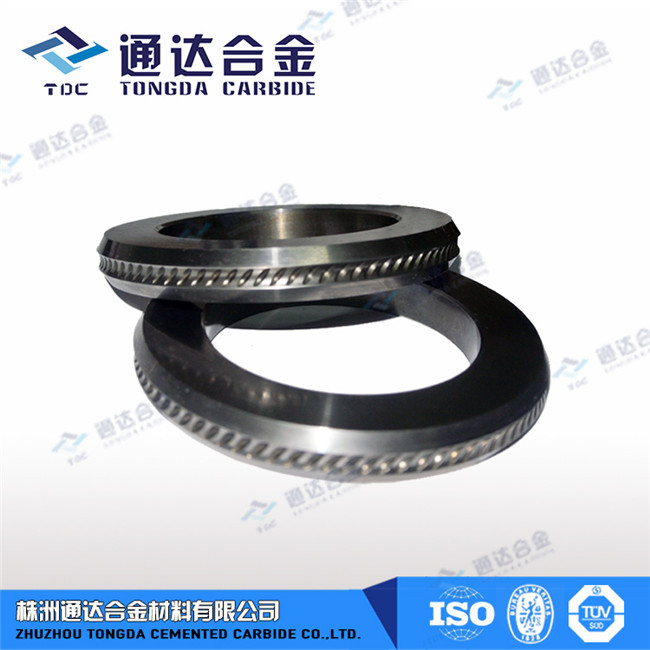

銆?銆?Our tungsten grinding rotor, pegs, dispersing tray, tungsten carbide dynamic and static ring, cone round turbo, are mainly used to coating, printing, painting, dying and on the equipment of oily product grinding and dispersion process.

銆?銆?All our products were best-sold to twenty more provinces in China, which not only help to solve manufacturer problems for customers sale, but also be honored as foreigner replacement by many customers.

銆?銆?Zhuzhou Tongda Cemented Carbide Co., Ltd is always insisting on the business idea of 鈥渋ntegrity industry, brand business, quality development鈥? and paying attention to the enterprise image and own brand construction. We keep a close relationship with all customers, and consider every client as a mentor, constantly strengthen the communication and cooperation, and provide the perfect service for them.

銆?銆?We focusing on providing the most effective solution for customers, are supposed to be a professional and diversified hard alloy manufacturer. We not only offer the standard products, but also make all kinds of customized proposal to meet customers needs together with customers themselves.