Cable Tray Cover Roll Forming Machine - No.1-1

Cable Tray Cover Roll Forming Machine For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale Cable Tray Cover Roll Forming Machine, Made in China, High Quality Products!, China Cable Tray Cover Roll Forming Machine,Cable Tray Roll Forming Machines, Supplier, Manufacturer.

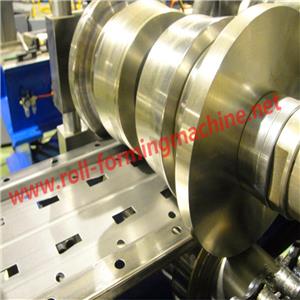

Equipment structure for the cable tray cover roll forming machine:??Equipment structure?decoiler---Leveler---Servo-feeder---Punching----outTable---Roll forming---cutting---Collection?Feeding machine?Width of material sheet: 100—600mm; Thickness of material sheet: 1.6mm~2.0 mm?Inner diameter: 508mm Range of expanding: ф480-520 mm?Maximum outer diameter: φ1300mm,Website:http://www.roll-formingmachine.net, loading: ≤6T?Working type: Hydraulic expansion, passive decoiler?Leveler?NCF800 Servo feeder?Function: material feeding?Feature: Uses the servo motor-driven .Multistage type feeding: May input 10 group of different feeding lengths, The liquid crystal touching screen demonstrated is advantageous for the change, establishes various technical parameters. The auto-induction start system and the punch press linkage (control punch press start).?Punching press of the cable tray cover roll forming machine?Technical parameter:?1. Forming station: about22stations (according to equipment requirements)?2. Width of feeding: 100~600mm?3. Axis of rollers: (according to equipment requirements)?4. Distance of two sides rollers: about 350-550mm?5. Power of motor: 22kw (5.5kwX4)?6. Production speed: 2-4m/min, the whole speed line is 10m/min in theory.?7. The roller forming machine consists of C profile and reinforcing rib.?Collection table?Structure: roller type with no power?Electric control system of the cable tray cover roll forming machine?

? ?a.Full line is controlled by PLC control system with touch screen operation to achieve the human and PLC interactive. The operator can monitor the setting program (programmable control) and modify the parameter to control the line. Also can check the running status, parameter and error indication etc...?

? ?b.Operation type: manual /auto two type switch. In manual position: can run the each part of the machine. In auto position: can run the full line. The emergency stop ensures the safe of the equipment and operator.?

? ?c. Machine side is

JIANGYIN DINGBO TECHNOLOGY CO., LTD

Address: Xingyuan Rd. Beiguo, Gushan Town, Jiangyin City, JiangSu Province, China, Jiangyin, JiangSu, China, 214414

Tel: 86-510-86952128

JIANGYIN DING BO TECHNOLOGY CO.,LTD is聽a manufacturer specialized in customizing聽all kinds of roll forming machines. With our advanced techniques and experienced staff,Website:http://www.roll-formingmachine.net, we can produce simple profiles as well as complex components with precision tolerances. Most of our main production staff have more than聽10 years of experience,聽which聽ensure good machine quality聽and high values for our customers.

Advantages of聽Our聽Roll Forming聽Machine:

Roll formed parts can have a variety of shapes, angles and curves. Many materials are suitable for our custom roll forming machines,such as produce color steel roof sheets, C/U/Z/M/T/L steel purlins, metal floor deck, cable tray, fire damper, rack pillars ect . We design products that best meet specific needs.

If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to聽build successful business relationships with new clients around the world in the near future.

Company Advantages:

1. Fast Delivery Time聽(25-40 days only)

2. Competitive Price聽(95% suppliers were defeated)

3.聽Good machine Quality聽( Panasonic, Siemens product equipped with our machines)

4. 24h* 7 After-sales聽Service聽(Support Email, Skype, Whatsapp, video meeting ect.)

http://www.roll-formingmachine.net