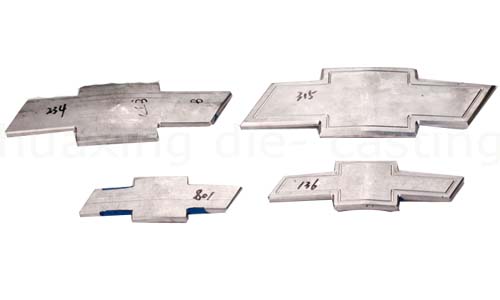

Auto Parts,Car Parts,Automobile Parts - HX-Z-AP07

Auto Parts,Car Parts,Automobile Parts For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale Auto Parts,Car Parts,Automobile Parts, Made in China, High Quality Products!, China Auto Parts, Auto Accessories Supplier, Manufacturer.

Die Casting Auto Part is durable and dimensionally stable, while maintaining close tolerances. They are also heat resistant.

Description:

We are professional to manufacture die casting parts as per customer's drawing or sample.

Production Process

Mold: design, making, pilot testing, approval, production

Die Casting: ingot, inspection, oven melting, die casting inspection, trimming, punching, deburring, machining (drilling, tapping, turning, milling, boring), inspection

Grinding & Polishing: vibration, wheel blasting, polishing, inspection

Treatment & Coating: varnishing, painting, powder coating, anodization, electric plating, inspection

Assembly: components assembly on request

Finishing: surface inspection, packing

Die casting process and our experienced technology, high technology equipment to be sure the precision dimension, good surface, and molded from complicated shapes.

Ningbo Yinzhou Huaxing Die-Casting Manufacturer

Address: No.218 Pugang road, chuangye industrial estate, Qiuai town, Ningbo, China , Ningbo, Zhejiang, China, 315101

Tel: 0086-574-88413046

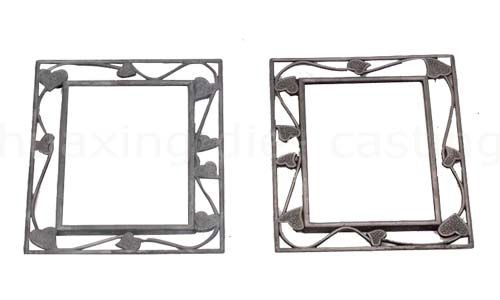

We are professional producer of moulding, manufacturing and processing for zinc and aluminum alloy die casting products, such as Auto Parts, Car Parts, Lighting Part, Ball Valve, Machining Part, Machine Part, Hardware Part, Hardware Tool, Photo Frame, Metal Crafts, Mirror, Decoration.

We know exactly the customers??requirement when they provide drawings and material specification. What?? more, our engineers can suggest the best process and technology.

Our factory area is approximately 5000sq meters. We have more than 10 sets of cold chamber machines and hot chamber machines, besides we also have other production equipments and QC equipments. The heaviest die casting finished products can be reach 5000g.

All of our products comply with ISO9001:2000 specifications and meet the market requirements with international standards. In order to expanding our market, we introduced low-pressure casting as another casting technology.

Through more than 10 years efforts, we have built a reputation for providing quality products, on time delivery, personal attention and competitive price for customers. This credit has brought many repeat customers all over world, particularly in Europe and U.S.A

Our principal is to take on responsibility from design to delivery for our customers.

Warmly welcome abroad customers to visit our factory to estimate our production capacity and products??quality.