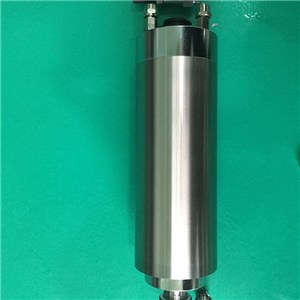

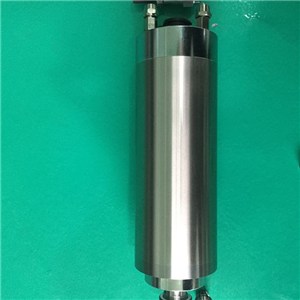

ATC Electric Spindle Machining Center - No.1-1

ATC Electric Spindle Machining Center For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale ATC Electric Spindle Machining Center, Made in China, High Quality Products!, China ATC Electric Spindle Machining Center,Electric Spindle Machining Center, Supplier, Manufacturer.

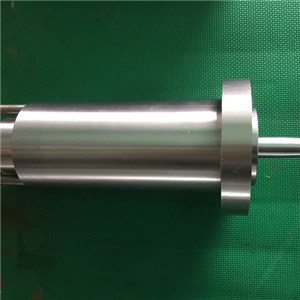

Jianken High-Speed Electricmotor Co.,Ltd is one of the leading atc electric spindle machining center manufacturers and suppliers in China,Website:http://www.jian-ken.com, providing with atc electric spindle machining center maintenance, welcome to buy customized atc electric spindle, atc spindle center from our factory, and you are also welcomed to consult the price with us.Characteristics of motorized spindle for machining center1 good starting performance, high torque, high efficiency2 the structure is reliable, the sealing performance is good, the precision is high3 low noise, small vibration, smooth operationMatters needing attention?1, using the environment should be dry, normal high speed motorized spindle surface should be kept clean.?2, the operator must have the skilled operation skill and the correct specification of operation.?3, when high speed motorized spindle is used to pass a low-speed rotation preheating, through the low speed rotation using grease fiber direction along the bearing running order, this can reduce fever and make full lubrication of the bearing. Instead, there is no sufficient lubrication, ball sliding inside the raceway, is not very good lubrication, easy to damage the bearing, which resulted in increased noise.?4, high speed motorized spindle must ensure adequate cooling. Water cooling method of motorized spindle, the water temperature more than 45 ℃ should be in the water, when the high-speed motorized spindle at high temperature for a long time, when you are working in a oil will accelerate the failure, eventually rotating noise increase, jitter, high-speed bearing damage and failure such as motor coil burned to death.?5, use the wear of cutting tool in machining, tool wear after continue to use, when the feed will be much on the high speed bearing axial force and radial force, speed up the bearing wear, which resulted in increased rotational noise, working long hours can make the spindle motor produces axial clearance.?Knife at 6,

Get QuoteJingjiang Jianken High-speed Electric Motor Co.,Ltd

Address: no.16 runjinggagn road,Hongguang industrial park,jingjiang,jiangsu, taizhou, jiagnsu, China, 214500

Tel: 86-0523-84385453

The Jingjiang Jianken High-speed Electric Motor Co.,Ltd is a manufacturer in combination with R&D and production,specialized in the manufacturing of the high-speed motorized spindles,motors and machines. Founded in 2002, the company has adhered to the development idea of 鈥淧eople-Oriented,Being Perfect and Customer Satisfaction-Oriented鈥?and has achieved the rapid growth through many years of efforts. With the precise machining equipment,scientific and reasonable process technologies, advanced testing methods and first-class assembly technology,together with the high-precision and high-speed ceramic ball bearings, the company has produced the JG series high-speed motors, high-speed motorized spindles for drilling, milling, grinding and carving processes. These motorized spindles are characterized by low noise,small vibration,large torque force and stable operation, with its speed up to 0.01-0.1 million rpm and the power up to 30kw. These products are widely used in the CNC machines,machinery mold processing centers,wood-working machines, centrifugal machines,glasses machinging, brush-marking, lockmarking and other industries and have won the praise from many manufacturers.

Website:http://www.jian-ken.com

http://www.jian-ken.com