Aluminum Die Casting of Lamp Heat Sink - NO

Aluminum Die Casting of Lamp Heat Sink For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale Aluminum Die Casting of Lamp Heat Sink, Made in China, High Quality Products!, China Aluminum Die Castings, Zinc Die Castings Supplier, Manufacturer.

Min. Order:2000 Piece/Pieces

Payment Type:T/T

Transportation:Ocean

Packaging:Standard exporting package, such as plywood box, plywood pallet, carton & bubble bags.

Delivery Time:30 Days

Place of Origin:Ningbo,China

Certificate:ISO9001

Product Description

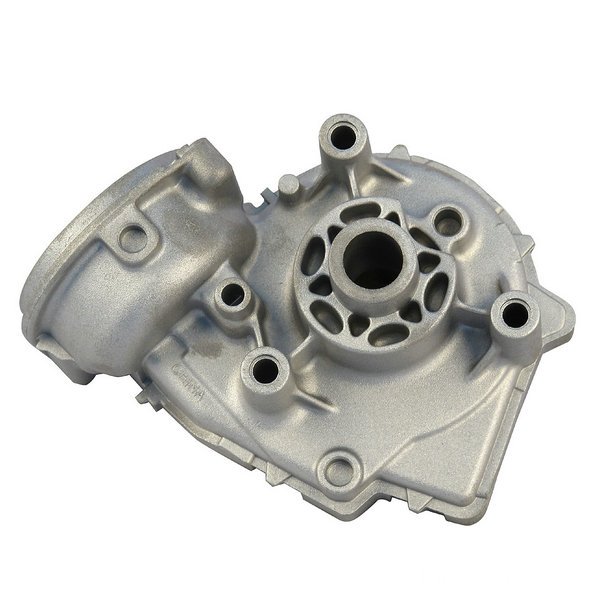

Aluminum Die Casting Lighting Accessories: Aluminum Die Casting of Lamp Heat Sink

Die casting Machine: 180 ton

2 parts per die

Material: A413

Product Dimensions: 98.7mm*46mm*46mm

Casting Precision: Grade GB-CT4

Machining Precision Screw Thread: H6

Technological Process: Die casting, Degate, Burring, Abrasive Cleaning, Powder Coating, CNC Machining (A process machining), Machining Center(B process machining), Cleaning, Packing, Delivery

Control Measure: First item inspection, Routing inspection, Final item inspection, Incoming test and Outgoing quality control

Inspection Equipment: CMM and Screw Gauge

Surface Treatment: Powder Painting

http://www.bldiecasting.com/aluminum-die-casting-lighting-parts/1219432.html

http://www.bldiecasting.com/aluminum-die-casting-lighting-parts/

Ningbo Zhenhai Bolang Metal Manufactory

Address: Guisi Industrial Zone, Luotuo Street, Zhenhai District, Ningbo, Zhejiang, China, ningbo, zhejiang, China, 315206

Tel: 86-0574-86556927

NINGBO ZHENHAI BOLANG METAL PRODUCT FACTORY was established in 2002. Bolang die casting specialize in Aluminum die casting, Zinc die casting parts, CNC machining parts as well as all kinds of surface treatment for more than ten years so that we have rich experience and capability in these areas. We have successively passed ISO9001 quality system. TECHNICAL EQUIPMENT: We have 4 sets of High-performance die casting machines with different tonnage ranging from 180T to 550T, over 8 sets of CNC Lathe and Brother CNC TAPPING CENTER, KIWA VERTICAL MACHINING CENTER, NIKKEN FOURTH AXIS ROTARY TABLE from Japan. In our testing center, we possess 1 set of high-precision CMM and other advanced testing devices such as spectrograph, tensile force testers, roughness measuring instruments etc. MATERIAL: We usually use A380, ADC-10, ADC-12, ADC-6, ADC-3, YL-102(LM20). SURFACE TREATMENT: We are skillful at chromed plated, painting, powder coating, anodizing, sand blast, shot blasting etc. PRODCUTS: We usually provide products about Auto parts, lighting parts, aviation parts, motorcycle parts, motor shell, communications equipment etc. And our products are mainly exported to countries such as USA, Europe (England, Germany, Italy, Belgium etc), Asia (Japan, Korea etc)