Advanced ceramic zirconia parts - N/A

Advanced ceramic zirconia parts For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale Advanced ceramic zirconia parts, Made in China, High Quality Products!, China Zirconium Oxide, precision parts Supplier, Manufacturer.

Zirconium Oxide ZrO2 Ceramic Balls

Diameters are between:0.6-100mm

Material can be:

Si3N4,AL2O3,SiC,ZrO2

Custom accept

Zirconium Oxide ZrO2 Ceramic Balls

1, zirconium oxide material characteristics:

Pure ZrO2 is white, including impurity yellow or gray, zirconia 5.6 g/cm3 density, melting point 2715 °C. ZrO2 has good heat resistance, the insulation, corrosion resistance.

Usually the application of zirconium oxide structure ceramic material is TZP (four party zirconia polycrystalline). Materials to suppress the grain is growing up and stable zirconia crystal shape, the change is all part of the PSZ (stabilization zirconia) or all the more in the highest toughness crystal ceramics.

Zirconia ceramics density 5.95-6.05 g/cm3 in between, four often used to produce ceramic ball materials (Si3N4, SiC, ZrO2, Al2O3, zirconia) the toughness of the highest, 8 MPa ? m 1/2 above, coefficient of thermal expansion, 10.5 x 10-6 / °C, close to the metal thermal expansion coefficient, and with the cooperation of metal is good, but the size stability with temperature changes greatly, rolling contact fatigue failure form for destructive chipped in some key occasion, as the azotized silicon material stability.

Zirconia ceramics has self-lubricity, can solve the pollution caused by the lubrication medium and add inconvenience; Good corrosion resistance, alkali, acid in medium medium, and water in the media such as you can also use; High temperature resistant, zirconia ceramics in 600 °C, strength, hardness almost unchanged; Don& acute;t magnetic, insulation, magnetic field can also use, not conduct electricity.

2, the applicable areas:

Semiconductor, LCD manufacturing equipment, plating equipment, synthetic fiber manufacturing equipment, optical film equipment, various kinds of heat treatment furnace, vacuum equipment; Can also be used in composite bearing, processing with tools, all kinds of parts, all kinds of valve, vacuum equipment and all kinds of environments.

Xiamen Innovacera Advanced Materials Co.,Ltd

Address: Room 615,No.398 Jiahe Road Huli district, Xiamen , Fujian, China, 361006

Tel: 0086 592 5589731

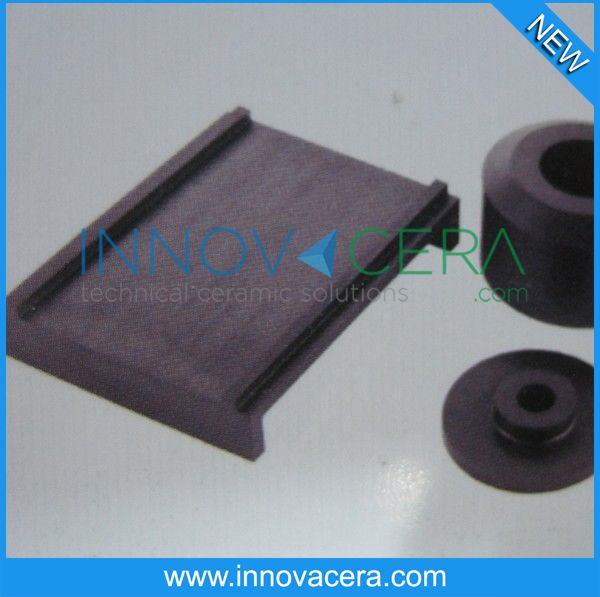

As a manufacturer of technical ceramic products, Innovacera main business is produce metallization ceramics and ceramics components as customer request.

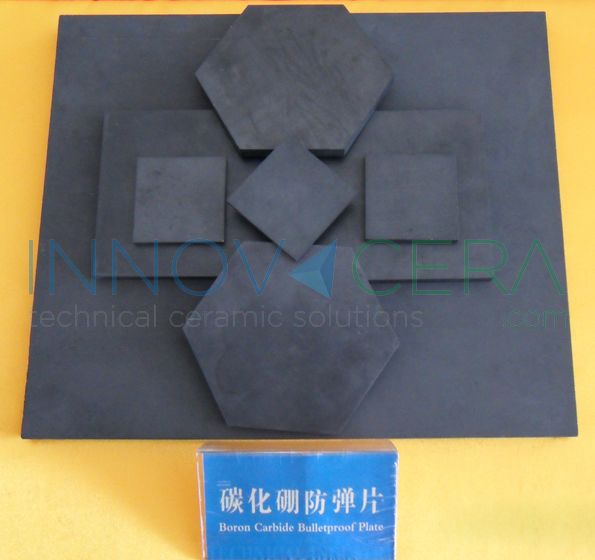

Ceramic materials offer unprecedented possibilities for many industries, especially when products and components with extreme material properties are required. ceramic material including Aluminium Oxide, Zirconium Oxide, Silicon Carbide, Boron Carbide, Silicon Nitride and Boron Nitride.

Innovacera offer you a wide range of production facilities like extrusion, injection moulding, pressing and casting. Depending on product geometry and quantities, we will choose the suitable technique for your products.

For the final finishing of the parts we use CNC machining centres, equipped with diamond tools in order to meet high accuracies.

Innovacera products widely used in Aerospace, Research, Food Processing, Fluid Handling, Scientific, Automotive, Defense, Thermal Processing, Electrical, Process Control, Textile & Wire, Pulp & Paper, Mechanical, Glass Processing, Mineral Processing as well as smaller niche markets.

Our goal is to put the often extreme properties of technical ceramics to the best use.