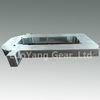

3.5 Ton Casting Steel Machining Body CNC Machined Components for the Gear Reducer - GEARMACHINING13

3.5 Ton Casting Steel Machining Body CNC Machined Components for the Gear Reducer For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale 3.5 Ton Casting Steel Machining Body CNC Machined Components for the Gear Reducer, Made in China, High Quality Products!, China cheap prodocuts, china suppliers Supplier, Manufacturer.

.5 Ton Casting Steel Machining Body for the Gear Reducer

?

Metal Machining Parts / CNC Machining Parts / Precision Machining Parts

?

1. metal machining parts strictly according to customer’s drawing,packing and quality request;

2. Tolerance: Can be kept in +/-0.005mm;

3. The most advanced CMM inspector to ensure the quality;

4. Experienced technology engineers and well trained workers;

5. Fast and timely delivery. Speedily&professional service;

6. Give customer professional suggestion while in the process of customer designing to save costs.Our freight price is often 30-50% lower than customer& acute;s;

7. Customers can use PAYPAL and other online payment platform to pay a small amount of sample fee to shorten the sample production time;

8. Quality assurance in accordance with ISO9001:2008.

?

Gear Machining Center

- - - -

NAME | Steel Fabrication |

Material | Stainless steel, iron ( SPCC, SECC, SPTE, tinplate), aluminum alloy, red copper, brass, bronze alloy are available. |

Manufacturing | CNC Laser Cutting ,Stamping, Punching , Bending, turning ,Welding, roll-in, surface treatment, and other General Fabrication Service |

Surface Treatment | Powder coating, Zinc plating, hot-dip, Silkscreen, polishing and so on. |

Equipment | CNC machining center, CNC lathe, grinding machine, automatic lathe machine, conventional lathe machine,? milling machine, drilling machine, EDM, wire-cutting machine, CNC? bending machine etc. |

Testing machine | Digital Height Gauge, caliper,?Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on. |

Business scope | CNC center machining, drilling, turning, grinding, tapping, mould design and processing, casting,? sheet mental working etc |

Application | Automobile, marine, construction, mining, electric, electronic, furniture industry etc. |

Quality control | ISO90001:2008 and ERP management systems are strictly carried out. Stable quality and on-time delivery have won trusts and supports from our customers home and overseas. |

OEM | OEM service based on customer& acute;s drawing or samples |

- - - -

?

Thank you very much for your time to visit our website.

?

FREE?TECHNICAL?SUPPORT ?

You?receive?expert?help?from?the?people?who?designed?the?product.

?

TO?PLACE?AN?ORDER

1.??Please?contact?us?by?email?or?phone?to?order.?In?your?email,?please?provide?your?full?shipping?address,?telephone?number?and?the?product(s)?you?are?interested?in.?Drawing?file?as?below?can?send?to?check:?.iges?.dxf?.dwg?.pdf?.jpeg?.png?.?We?will?quote?your?item?and?shipping?charge?if?it?is?needed.

?

2.??We?can?accept?payment?through?T/T.

You?may?also?send?a?cashier& acute;s?check?or?money?order?directly?to?us.???All?checks?including?e-checks?are?subject?to?verification,?which?may?cause?delay?in?processing.??International?payment?must?be?made?through?T/T.

?

3.??Once?you?pay,?we?will?begin?to?manufacture?and?ship?your?order?between?10?and?15?business?days?and?provide?you?with?a?tracking?number.??No?further?action?is?needed?on?your?part.

?

CNC Machining Metal Detailed?specification

?

1). We specialized in aluminum precision machining for 9 years.

2). Machining: precision CNC machining, punching and stamping, milling, tapping, polishing, according to customers& acute; drawings or samples.

3). Material: aluminum alloy 6063,6061,5052,7075,3003, according to customer request

4). Finish: mill finishing, anodizing, brushing, sandblasting, polishing, powder coating and painting according to customer& acute;s requirements.

5). High quality control:100% inspection before shipping.

6). Competitive price, fast delivery time, good service.?

7). Aluminum enclosure, radiator/heat sink and different enclosure panels, machining metal parts are our main products.?

8). OEM service is available, we can produce by customers& acute; drawing.

?

?

?

Process?flow:

?

1. Drawing confirmation

2. Sample?confirmation?

3. Mass?production?

4. Cutting

5. Deep?processing?(?punching?and?stamping,?milling,?tapping,?CNC?machining,?polishing.)

6. Surface?treatment?(wire?drawing,?deburring,?anodizing,?powder?coating,?silk-screen?print.)?

7. QC?inspection?in?housing?or?third?party?inspection?as?requested.

8. Packing.

?

Our?capability

Cutting?,?bending?,?tapping?,?milling?,?drilling?,?anodizing?,?wet?painting?,?powder?coating?,?silk-screen?printing?,?engraving?,?packaging

?....................................................................................................................?

Factory?scale

?

factory?occupies?over?3000sqm

with?more?than?50?employees?passionately?working?on?production?lines?&?departments

ISO?9000:2000?certificated

annual?turnover?US$?10??million

?

Advantage

?

complete?production?equipments?from?materials&profiles?to?secondary?operations

1/5?of?our?workers?have?above?10?years?experience?in?this?field

strict?and?complete?inspections?from?material?compositions?to?metal?properties,?specifications?&?finishing?

ISO?strictly?carried?in?every?step

strong?production?capacity?to?ensure?timely?delivery

LuoYang Gear Machinery Equipment.,Ltd

Address: 1302-5-5 ChangAn Road DianXi Zone LuoYang Henan China, luoyang, Henan, China, 471000

Tel: 86-379-64955360

LuoYang Gear Machining center have much experience in the manufacture of Machining production in various materials to companies in the China and worldwide. We are locate in the LuoYang Of China, Heavy Industry town of China. We are the firm Supplier of CITIC and METSO, All of Machining Production from our company with be with SGS Certificate or CITIC Inspection Report. For the Technical support, we can offer the Before-Sales and After-Sales. LuoYang Gear Machining center can undertake more critical require For precision and Big Size. And we also can arrange CITIC production. All of Machining Parts from LuoYang Gear Machining center As Below:

Bevel Gear(Straight/Helical Bevel Gears within 7M, Zero Bevel Gears within 2M,Spiral Bevel Gears-within 2M, and Other Special Bevel Gear)

Spur Gear,planetary gear,sun gear,Precision gears,internal gear,semi-autogenous mill Gear,Mining machinery gear,Helical gear,spiral wheel,Cylindrical helical gear,Herringbone gear,Hypoid gear,Cylindrical Gears,Reduction Gears

Main Shaft, Gear Shaft, Gear Racks,Ball mill gear shaft,Straight gear shaft,Helical Gear Shaft, Herringbone gear shaft, bevel gear shaft