3/4-inch bimetal thermostat used in water heater/washing machine/clothes dryer

KSD302R-453(45°)

302 series bimetal thermostats are also called 3/4 inch thermostats which can replace the 60T products of Emerson (T.O.D.) Company in the United States. The bimetal thermostat carries a large current, the maximum can reach 60A, can be applied to the highest power 10KW electrical equipment. The bimetal thermostat can also be set according to the customer's needs.

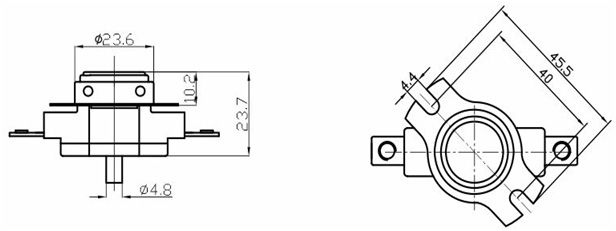

Product Drawings

Working Principle

It is a kind of thermostat with bimetal as the temperature-sensitive component, when the appliance is working normally, the bimetal is in the free state, the contact is in the closed/disconnected state, when the temperature reaches the action temperature, the bimetal is heated by the internal stress and acts quickly to open/close the contact, cut off/connect the circuit, thus playing a role in bimetal thermostat. When the appliance cools down to the reset temperature, the contacts automatically close/open to restore normal operation. Several of these bimetal thermostats also have dual temperature protection, when the bimetal thermostat part of the failure to a certain temperature can not cut off the circuit, the temperature continues to rise to another set of temperature limit set temperature, start the secondary protection, cut off the circuit.

Application Areas:

Water heaters, instantaneous water heaters, clothes dryers, ovens, welding machines, heaters and other high-power household appliances and small machinery.

Services

- Sample test: Because of the specialness of bimetal thermostats, we need to conduct matching installation test before an order is placed. Through such test, we can also make sure that the performance of our products, temperature and other parameters are qualified in line with customers’ requirements.

- Special requirements: We can design molds according to customers’ drawings. If customers do not have drawings, but have samples, they need to send the samples to our engineers. We can measure the size and design the drawing, and then design the mold based on the drawing.

- After-sales service: If the temperature of the product needs to be changed, please feel free to contact us and we will always be patient in serving you. Instead of engaging in one-off business, we are seeking long-term cooperation, from which we can achieve a win-win situation.

- Payment: Currently we support T/T payment, and demand an advance deposit which is 30% to 50% of the total amount. The rest shall be paid off before delivery. As for other payment methods, it can be determined according to the sum of the order and the actual situation.

Product Parameters

| Electrical parameters | AC250V/400V 50-60HZ 15A-60A (resistive load) |

| Product certification | UL,CUL,TUV,CE,CQC |

| Action temperature range | 0-160 ℃ (optional), temperature accuracy: ± 3 ± 5 ± 10 ℃ |

| Reply and action temperature difference | 10-50℃ (optional) |

| Wiring | plug terminal 6.3 (bend 0 ~ 90 ° optional); thickness 0.8-1.0mm optional) |

| Service life | ≥ 100,000 times |

| Electrical strength | AC 50Hz 2500V over 1min, no flicker, no breakdown |

| Contact resistance | ≤ 50mΩ |

| Insulation resistance | ≥ 100MΩ |

| Contact form | normally closed type: temperature rise, contact disconnection, temperature drop, contact connection; Normally open type: temperature rise, contact on, temperature drop, contact off |

Installation:

contact temperature-sensitive installation, or air temperature-sensitive installation

Attension:

(1) Grounding method: connect the metal cover of the thermostat with the grounded metal parts of the equipment.

(2) When using contact temperature-sensitive installation, the metal cover surface should be made close to the installation surface of the controlled device, and in order to ensure the temperature-sensitive effect, the temperature-sensitive surface should be coated with heat-conducting silicone grease or other heat-conducting medium with similar performance.

(3) The top of the cover should not be collapsed, loosened or deformed during installation so as not to affect the performance.

(4) The liquid must not be allowed to penetrate into the interior of the temperature controller, the shell must not be cracked, and the shape of the external terminals must not be changed arbitrarily.

(5)The product should be stored in a warehouse with relative humidity less than 90% and ambient temperature below 40℃ ventilated, clean, dry and without corrosive gas.

(7) The use of the process can not bend the terminals, otherwise it will affect the reliability of the electrical connection

Packing Details

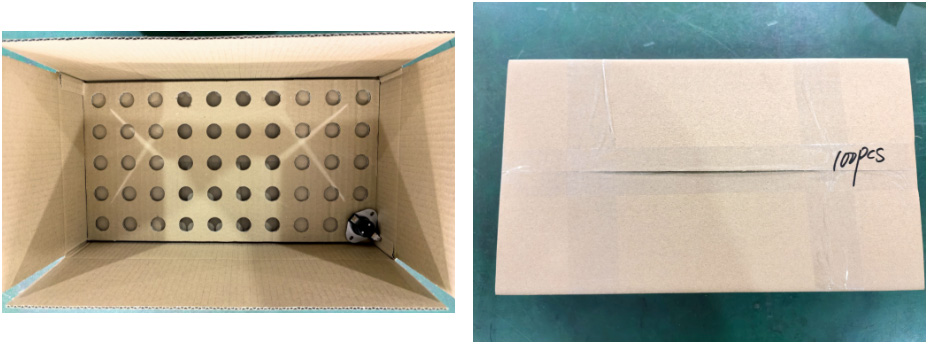

Inner packing:

Out packing: