0.3 mm - 0.8 mm Double Layer PU Sandwich Panel Machine for Corrugated Panel - RH-PU-18

0.3 mm - 0.8 mm Double Layer PU Sandwich Panel Machine for Corrugated Panel For Sale, Most Competitive Price, Fast Delivery, Custom Service, Wholesale 0.3 mm - 0.8 mm Double Layer PU Sandwich Panel Machine for Corrugated Panel, Made in China, High Quality Products!, China cheap prodocuts, china suppliers Supplier, Manufacturer.

?

0.3 mm - 0.8 mm Double Layer PU Sandwich Panel Machine for Corrugated Panel?

?

?

Specifications of?producible?sandwich panels:?

?

?Max. length?? 6000mm

?Max width???? 1000mm

?Thickness???? 30mm

?

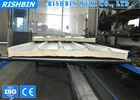

Roll forming machine (Two sets for two profiles)

?

?

?

Details of Roll Forming Machines

?

?

Main Roller Forming Machines--------------Two sets

?

1: Working speed: 12-15m/min (not contain cutting)

2:?Coil width: 1220/1100mm?? effective width: 1000mm

3: roll station: 20/13 stations

4: material of roller: grade 45 steel, polished and coated with chrome

5:material of main shaft:45﹟ steel?? diameter roller: Ф70mm

6: main power: 5.5KW??

7: forming thickness: 0.3mm—0.8mm zinc and color steel, G250MPA

8: Transmission: by single Chains 1.0 inch

9: feeding and guide: surface polished and coated with chrome

10: machine drive parts adopt protect cover

11: machine adopt new station with chrome

12: size of main machine: max 8000x1300x1200(mm)?? L x W x H

13: weight: about 5500Kgs

14: color of machine: blue (also can choose by customer request)

15: machine should be with four legs (made from metal) in 350mm

?

?

Uncoiler For Material? Feeding --------------Two sets

# # Dimensions: 1700mm*1000mm*800mm

# Width of feeding:1300mm

# Capability: 5 Ton

# Inter diameter: 450-510mm

# Mode of expand &fight: inner expand &fight by manual

# Way of feeding: manual

?

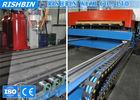

PU Insulation part

?

?

?

Constituents of Equipment

?

One “1+1” double-layer laminator for CORRUGATED panel

?

The laminator is used to make sandwich panels with the max. lenth of 6m, max. width of 1.0m and the thickness 30mm.

?

1.?Main technical parameters

Thickness of a sandwich panel????? 30mm

Max bearing force?????????????? 0.2Mpa/cm2

Moving speed of worktable??????? 15-20m/min

Pressing speed????????????????? 10~30mm/s

Working temperature of worktable?? 0~50℃

?

2.?Main machine

To be made up of the frame, chassis, slanting mechanism, rails and beam.

2. 1 Worktable

Worktables are made of extruded aluminum alloy.

worktable (is fixed),manual-feeding ,and mould locators are provided.

2. 2 Worktable heating system

It is made up of the medium heating installation, pump units, pipes and suitable temperature control. (Two sets, one on the right, the other on the left)

2. 3 Electric control system

Adopting central control by a panel, the system is equipped with fitting press buttons, relays, temperature control instrument, etc..

?

Contact us

?

For more information, please contact us freely.

?

Skype: sarahrishbin

Mobile: +86-18118899986

E-mail: sarahrishbin@gmail.com

RISHBIN WUXI CO., LTD

Address: No. 10, Changjiang Rd, Wuxi, Jiangsu, China, 214000

Tel: 86-510-85853379

Welcome to Rishbin, an innovative supplier in roll forming machinery markets.

Rishbin was founded in 1999. With more than ten years' development, now it becomes a leading professional supplier in the field of roll forming machinery industry, and exports its quality production line to the markets all over the world.

Find below what we are working as and what we are able to provide:

1) Supplier (manufacturer and exporter): The most thing we take pride in is, with many years鈥?experience in exporting to overseas markets, Rishbin has built a very good business relationship and wide connections with hundreds of quality manufacturers in China, which has covered many kinds of roll forming machinery. In 2005, Rishbin built its own manufacturing plant in Wuxi, Jiangsu Province, which improves its function as not only a trading house but also a professional manufacturer.